The studio, once defined by dust and flame, now hums with a different energy. A 3D printer deposits porcelain slurry in precise, impossible layers while a potter’s hands rest momentarily on the workbench. This juxtaposition isn’t about replacement; it’s a profound expansion. The field of ceramics is undergoing a multi-vector shift, moving not in a linear march but through a simultaneous deepening of ancestral material knowledge and a widening of technological possibility. The conversation has evolved beyond mere technique into the dynamic realm of material intelligence, where the ancient and the algorithmic are forging a new, collaborative future for the craft.

The Data-Infused Material: Clay as a Programmable Medium

Gone are the days of choosing merely between a generic red or white clay. The most compelling work in contemporary ceramics now emerges from hyper-specific material formulations, where clay is treated less as a found substance and more as a programmable medium. This shift represents a fundamental change in the potter’s relationship with their primary material. Artists, small-scale manufacturers, and even hobbyists are increasingly collaborating with geologists and material scientists to engineer clay bodies with predetermined behaviors, transforming intuition into informed interaction.

Consider a studio in Oregon that has developed a line of six distinct porcelain blends. Each bag comes with a QR code linking to a detailed data sheet: documented shrinkage rates, thermal expansion coefficients, and optimal glaze pairings. This isn’t a move toward cold, industrial standardization. Instead, it’s about empowering the maker with choice. A potter now selects a clay not just for its plasticity or color in the raw state, but for how it will perform in a precise dialogue with a specific glaze chemistry at cone 10. The element of kiln-chance is reduced from a high-stakes gamble to a calculated variable. As noted by material science researchers, this “democratization of material data” allows for greater reproducibility and innovation outside traditional industrial labs. The material itself becomes an active partner in the creative process, its once-hidden language now partially decoded and accessible.

This scientific approach is filtering down to community studios and individual artists. A potter in New Mexico, for instance, meticulously tests local clays, blending them with measured additions of sand or grog to combat cracking in the arid climate. She shares her findings in an open-source online database, contributing to a collective, growing body of knowledge. This mirrors a broader trend in materials science, where accessible tools are enabling citizen science. The World Health Organization has even highlighted the role of local material knowledge in developing sustainable, culturally appropriate technologies, a principle that applies directly to ceramics. When you understand that a clay’s iron content dictates not only its color but also its maturation temperature, you move from simply using clay to conversing with it.

Precise Imperfection and the Redefinition of the Handmade

Paradoxically, the widespread embrace of digital precision has not erased the value of the handmade mark; it has reframed it. When a form can be rendered with flawless, machined symmetry, the slight wobble of a wheel-thrown pot, the trace of a finger in wet slip, or the subtle variation of an ash glaze carries new weight and intention. The handmade mark is no longer the default, and therefore not the only evidence of human touch. It has become a deliberate aesthetic choice, one option in a vast toolkit.

This has given rise to sophisticated hybrid methodologies that choreograph a conversation between the capabilities of the machine and the irreproducible nuances of handwork. An artist might 3D-print a complex, structurally sound armature—a form impossible to coil or throw—and then hand-build over it with a coarse, groggy stoneware. The final piece celebrates the stark contrast between the hidden, perfect skeleton and the expressive, tactile skin. The goal isn’t to conceal the machine’s role but to integrate it. In this new paradigm, a ‘flaw’ is not a mistake to be hidden but a deliberate punctuation mark in an ongoing dialogue between control and spontaneity.

This redefinition challenges purist notions of authenticity. A mug can be born from a digital model, printed in clay, and then lovingly altered by hand—a thumbprint pressed into its side to create a perfect ergonomic grip. Its authenticity lies not in its exclusive origin from a wheel, but in the holistic intention of its maker. The story of a Japanese master who uses a CNC router to carve impossibly intricate negative spaces into thick slabs, which he then finishes with a centuries-old polishing technique, exemplifies this synthesis. The tool executes a superhuman task, but the artist’s eye guides every step.

“We’re not asking ‘what can the wheel make?’ anymore,” notes ceramicist and digital fabrication researcher Anya Petrova. “We’re asking ‘what does this idea need to be?’ Sometimes the answer is a thousand-year-old hand-coiling technique. Sometimes it’s an algorithmically generated lattice that can only be realized in clay through a binder jet printer. The material is constant; the methods are now a vast and neutral toolkit. My last series used a motion-capture suit to translate the gestures of a dancer into volumetric data, which was then printed in porcelain. The final piece holds a specific, fleeting movement forever—something neither the wheel nor my hands alone could ever capture.”

Sustainability Through Advanced Material Science

The drive for material intelligence is powerfully aligned with a growing imperative for sustainability. The ceramics industry has a significant environmental footprint, from the energy intensity of kiln firing to the mining of raw materials. New technologies and a deeper understanding of material chemistry are offering pathways to reduce this impact. Researchers are developing lower-fire clay bodies and glazes that mature at hundreds of degrees lower than traditional stoneware temperatures, dramatically cutting energy use. There is also exciting work in creating durable, vitrified ceramics from 100% post-industrial waste streams, such as glass dust or mine tailings, transforming a liability into a valuable resource.

For the studio potter, this translates to practical choices. Sourcing clay locally, or reclaiming and re-engineering your own studio waste into a new “studio blend,” reduces transportation emissions and landfill use. Exploring wood ash or other locally sourced wild materials for glazing connects your work to its environment in a tangible way. A collective in Iceland, for instance, formulates glazes using volcanic ash and geothermal silica, creating surfaces that are uniquely of that place. Their work demonstrates that sustainability isn’t just a constraint; it can be a profound source of aesthetic and conceptual inspiration, creating a direct material narrative about origin and responsibility.

Innovation in this area is accelerating. A recent study published in the Journal of the European Ceramic Society detailed a method for creating robust ceramic tiles from recycled glass and sewage sludge, addressing two waste streams simultaneously. While such industrial-scale solutions may seem distant from the studio, the principle is the same: understanding material composition unlocks new, circular possibilities. Even simple acts, like using a digitally monitored kiln to optimize firing schedules, contribute to a more efficient practice. Sustainability is becoming embedded in the craft’s very methodology.

Actionable Insights: Blending Old and New in Your Practice

This convergence of traditions need not be confined to high-tech studios. Potters at any level can explore this expanded mindset. Start by treating your material with a scientist’s curiosity. Document your process rigorously: weigh your dry and wet clay pieces, note shrinkage percentages, and keep detailed glaze logs with photos of results. This simple act of data collection builds your personal material intelligence.

Experiment with hybrid making. Use a 3D-printed or laser-cut template to create precise paper stencils for complex sgraffito designs on a hand-thrown form. Employ a digital moisture meter to achieve perfect leather-hard consistency for carving, every single time. If you don’t have a 3D printer, many local makerspaces or libraries offer access. The initial step is simply to break down the artificial barrier between “craft” and “technology” in your mind.

As a UNESCO report on safeguarding intangible cultural heritage emphasizes, innovation is key to the vitality and continuity of craft traditions. The story of a young potter in Ghana illustrates this beautifully. She uses smartphone apps to analyze the mineral content of local clays her community has used for generations, then cross-references this with global glaze databases to develop vibrant, stable glazes that honor her heritage while achieving new, reliable results for her functional ware. This is material intelligence in action, rooted in place but connected to a global knowledge network. Her grandmother’s intuitive knowledge of which clay fires strong meets her own systematic testing, creating a living lineage.

Another practical tip is to explore digital design tools, even free ones, to plan complex forms or surface patterns. Sketching a vase in a simple 3D modeling program can help you visualize proportions and volumes before you touch clay, reducing material waste. You can then choose to realize that design by hand, using the digital model as a precise guide, or output it to a printer. The key is to see these tools not as an end, but as extensions of your creative intent.

The Expanding Ecosystem: From Studio to Smart Factory

This technological integration is reshaping the entire ceramics ecosystem, blurring the lines between the artisan studio, the design studio, and the factory floor. Digital fabrication tools like 3D printing and CNC milling are enabling small-batch or even one-off production of highly complex forms that were previously only economical in mass production. This democratizes access to sophisticated manufacturing. A designer can now create a prototype digitally, test it through 3D printing in clay, and move to limited production without the need for expensive plaster molds or industrial tooling.

Meanwhile, large manufacturers are looking to the nuanced surfaces and aesthetic depth of studio pottery to add value and authenticity to their lines. This two-way flow of influence enriches the entire field. A high-end tableware company might commission an artist known for her organic, cratered glazes to develop a finish for a production line, translating a studio aesthetic for a broader audience. Conversely, an artist might adopt an industrial-grade pug mill to perfectly recycle and de-air tons of clay for a large-scale installation.

Platforms like Statista track the steady growth of the “maker” and craft technology market, indicating this is more than a niche trend. It’s a structural shift in how objects are designed, prototyped, and produced. The local potter selling custom, 3D-printed lamp bases alongside their wheel-thrown mugs is participating in this new, hybrid economy where scale is fluid and customization is king. This ecosystem also fosters new collaborations, like those between ceramicists and engineers to develop ceramic components for aerospace or medical devices, pushing the material’s performance boundaries in ways that feedback into artistic practice.

The Enduring Human Core in a Digital Age

Amidst the talk of data, algorithms, and printers, the human element remains the irreducible core of ceramics. Technology provides new tools, but the decisions—the aesthetic judgments, the emotional resonance, the conceptual depth—are profoundly human. The warmth of a cup’s curve as it meets the lip, the visual weight of a vase on a shelf, the narrative embedded in a sculptural form; these are territories where human sensibility reigns supreme.

Material intelligence does not create emotion; it provides a richer vocabulary with which to express it. A potter who understands glaze chemistry at a molecular level can more reliably evoke the deep, tranquil blue of a twilight sky or the chaotic crackle of ice. The data serves the vision. This is evident in the work of artists who use digital scanning to capture the form of a weathered stone or a crumbling wall, then reproduce it in porcelain. The technology captures exact detail, but the artist’s choice of subject, scale, and material transformation imbues the object with poetry and commentary.

The future of ceramics lies not in a choice between the hand and the machine, but in a masterful synthesis of both. It is a future where material intelligence allows artists to speak through clay with greater clarity and range than ever before. The studio continues to hum, a symphony now composed of the whirring of a printer, the soft slap of wet clay, and the quiet, focused breath of a maker deciding what comes next. The flame in the kiln, ancient and essential, will still transform it all, fusing these disparate threads into a single, coherent whole. The object that emerges carries within it the entire story: the data, the decision, the human touch, and the elemental fire—a true testament to the evolving, enduring intelligence of making.

You may also like

Guangxi Zhuang Brocade Handmade Tote – Ethnic Boho Large-Capacity Shoulder Bag

Original price was: $172.00.$150.00Current price is: $150.00. Add to cartBambooSoundBoost Portable Amplifier

Original price was: $96.00.$66.00Current price is: $66.00. Add to cartAncient Craft Herbal Scented Bead Bracelet with Gold Rutile Quartz, Paired with Sterling Silver (925) Hook Earrings

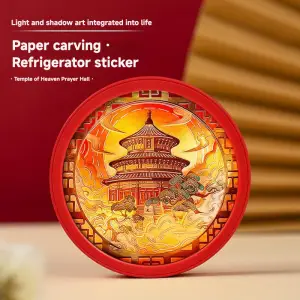

Original price was: $322.00.$198.00Current price is: $198.00. Add to cartThe Palace Museum Paper-Cut Light Art Fridge Magnets: Chinese Cultural Style Creative Gift Series

Price range: $27.00 through $36.00 Select options This product has multiple variants. The options may be chosen on the product pageAncient Craftsmanship & ICH Herbal Beads Bracelet with Yellow Citrine & Silver Filigree Cloud-Patterned Luck-Boosting Beads

Original price was: $128.00.$89.00Current price is: $89.00. Add to cartHandwoven Zhuang Brocade Tote Bag – Large-Capacity Boho Shoulder Bag

Original price was: $178.00.$154.00Current price is: $154.00. Add to cart