A delicate silver thread traces a precise, fractal pattern across a carbon fiber substrate. This isn’t a decorative flourish on a garment; it’s a functional antenna, its conductive pathway determining signal strength for a wearable medical monitor. This single image captures a fundamental shift. Embroidery, one of humanity’s oldest technologies, is being re-engineered from the inside out, moving from pure ornamentation to a form of material intelligence. The needle and thread, once tools of artistic expression and cultural storytelling, are becoming instruments of engineering, data storage, and sensory interface. This evolution is not a replacement of tradition but a radical expansion of its potential, weaving ancient craft into the very fabric of our technological future.

Embedded Function: When Stitch Becomes System

The transformation is most visible in the migration of embroidery into hard-tech applications where performance is paramount. Consider the aerospace sector, where every gram counts and reliability is non-negotiable. Here, embroidery machines, guided by CAD files with micron-level precision, are depositing threads that serve as structural reinforcement within composite panels. The stitch pattern—whether a herringbone, chain, or satin—isn’t chosen for its visual appeal but for its load-bearing characteristics. A single square meter of a modern aircraft interior panel might contain over three kilometers of high-tenacity polyester thread, stitched in a specific matrix to dampen vibration and resist delamination. The ‘fabric’ is no longer just a base; it’s an engineered component, with the embroidery providing its tensile logic.

This principle extends far beyond the fuselage. In automotive engineering, embroidered substrates are used to create lightweight, moldable interior components that combine aesthetic finish with acoustic insulation. In architecture, tensile structures and architectural meshes are being reinforced with robotic embroidery, allowing for complex, durable forms that were previously impossible. The stitch has become a fundamental building element, a way to dictate strength, flexibility, and behavior from within a material’s structure. It’s a quiet revolution happening not on assembly lines, but within the very layers of the materials themselves.

The Data Layer: Stitching Information into Form

Perhaps more profound is embroidery’s emergence as a medium for embedding data directly into objects. This goes far beyond attaching a simple RFID tag. Researchers are developing methods to encode digital information—from manufacturing provenance and supply chain logs to full maintenance schedules—directly into the stitch patterns themselves. A team at ETH Zurich demonstrated a jacket where the decorative floral motif on the sleeve contained a scannable QR code, stitched using a binary sequence of reflective and non-reflective threads. This isn’t just a clever party trick; it’s a paradigm for durable product identity.

On an industrial scale, critical assets like wind turbine blades, pipeline insulation, or composite bridges are being ‘tagged’ with embroidered identifiers. Unlike a printed label or glued chip, this information is woven into the material, able to withstand decades of UV exposure, extreme temperatures, and physical abrasion. It creates a permanent, inseparable link between the physical object and its digital twin in a database. The thread becomes a readable, resilient memory. As Dr. Anya Petrova, a materials engineer at an advanced textiles lab, observes: “We’ve stopped asking ‘what does it look like?’ and started asking ‘what can it do?’ The challenge now is designing the thread-substrate interface—the point where the intelligence of the stitch meets the properties of the base material. That junction is where true innovation happens.” This perspective reframes the embroiderer not as a decorator, but as a systems integrator, embedding history and instructions into the fiber of things.

The Conductive Stitch: Wearable Tech Gets Softer

One of the most dynamic frontiers is in conductive embroidery, which is fundamentally changing wearable technology. Instead of hard, rigid circuit boards and plastic sensors, engineers are creating circuits and sensors from threads plated with silver, copper, or other conductive materials. These can be seamlessly embroidered into clothing, upholstery, or medical textiles. The result is technology that is literally wearable—soft, flexible, washable, and comfortable. It dissolves the barrier between device and user.

Imagine a sports bra that monitors an athlete’s heart rate and respiration through embroidered sensors, transmitting data wirelessly via an embroidered antenna. Or consider smart workwear for firefighters, with embroidered heat sensors and vital sign monitors integrated into the uniform fabric, providing real-time safety data. In healthcare, the potential is staggering. Researchers are developing “smart” bandages that use conductive embroidery to monitor wound pH and temperature, signaling infection before it’s visible to the eye. For patients with chronic conditions, everyday clothing can provide continuous, unobtrusive health monitoring, improving both outcomes and quality of life. The World Health Organization has highlighted the growing need for remote patient monitoring technologies, especially in aging populations and low-resource settings, a need that soft, textile-based electronics are uniquely positioned to address. This isn’t speculative; companies are already bringing such products to clinical trials, signaling a near-future where our clothes are our first line of health defense.

Cultural Code and Modern Craft: Preserving Meaning in a Digital Age

Even as embroidery rockets into high-tech realms, its cultural and artistic heart beats stronger than ever. In communities worldwide, embroidery remains a vital language of identity, resistance, and memory. From the intricate Phulkari of Punjab to the symbolic Hmong story cloths, stitches carry histories and values. This cultural dimension is not being left behind; it’s engaging in a powerful dialogue with new technology.

Artists like Ekta Kaul use embroidery to map urban memory and migration patterns, stitching intricate city plans that tell human stories. Others are using digital embroidery machines to execute traditional patterns with new precision or to scale them for public art installations, making cultural heritage visible in contemporary spaces. There’s a growing “craft tech” movement where makers blend hand-stitching with LED circuits or conductive thread, creating interactive tapestries that light up when touched. This fusion honors the slowness and intention of handcraft while embracing the possibilities of interaction. As master embroiderer and social enterprise founder Paloma Gomez once noted, “Every stitch is a decision, a moment in time. When we mix that ancient rhythm with a blinking light or a sensor, we’re not just making a new object; we’re asking new questions about what tradition means today.” Organizations like UNESCO actively work to safeguard intangible cultural heritage, including traditional embroidery practices, recognizing their role in sustaining cultural diversity and creativity in our globalized world. The modern embroiderer thus operates in a rich continuum, connecting ancestral knowledge with futuristic applications.

Practical Pathways: From Hobby to High-Tech

This revolution isn’t confined to corporate labs and academic institutions. The tools and knowledge are increasingly accessible, creating new pathways for hobbyists, artists, and entrepreneurs. The barrier to entry is surprisingly low, inviting a wave of grassroots innovation.

- Start with Conductive Thread: The easiest entry point is a spool of conductive thread and a basic multimeter. You can hand-stitch a simple circuit to light an LED, creating a greeting card that lights up or a plush toy with a glowing heart. This tactile introduction demystifies electronics. Maker Sasha Lee, who runs workshops for teens, says, “The moment they sew a circuit that works, you see a switch flip. They realize they can build technology, not just consume it.”

- Explore Digital Embroidery Files: For those with access to a digital embroidery machine, online marketplaces offer thousands of designs. The next step is learning basic digitizing software to create your own patterns. Try converting a simple line drawing or logo into a stitch file—it teaches the logic of how shapes are built from thread paths and reveals the hidden geometry of imagery.

- Prototype a Smart Textile: Combine conductive embroidery with a tiny, programmable microcontroller like a LilyPad Arduino or Adafruit Gemma. You can embroider touch-sensitive patches on a sleeve to control a music player or create a bag with an embroidered panel that lights up when opened. Countless tutorials and open-source communities exist to guide these first projects, fostering collaboration over competition.

- Consider the Material Ecosystem: Advanced work requires thinking about the whole system. What base fabric are you using? How will it be washed? How does the stiffness of the conductive thread affect the drape of the cloth? Documenting these challenges and solutions is a valuable part of the process. This holistic view is what separates a simple project from a viable product.

The global market for smart textiles, which includes these embroidered applications, is projected to grow significantly, with Statista reporting a market value expected to reach tens of billions of dollars within the decade, driven by sectors from healthcare to sports. This growth signals not just a trend, but a lasting shift in how we integrate technology with the material world, creating opportunities for those skilled in both craft and code.

Sustainability and the Ethical Stitch

As the field advances, critical questions about sustainability and ethics come to the fore. The production of high-tech threads, especially conductive and optically functional ones, often involves complex chemistry and rare materials. The industry faces the pressing challenge of developing biodegradable substrates and recyclable conductive elements to prevent a new wave of e-waste in our textiles. The vision of a “circular” smart textile economy is paramount. Pioneering projects are exploring promising alternatives, such as using natural dyes with specific optical properties for data encoding or developing conductive threads from fungal-based mycelium or other bio-derived materials.

Furthermore, as production scales, ethical labor practices in both the traditional craft and new manufacturing sectors must be upheld. The value of the human hand in this high-tech equation cannot be overlooked or undervalued. The goal is to create a future where intelligent textiles enhance lives without exploiting people or poisoning the planet. This requires conscious design choices from the outset, considering the entire lifecycle of an embroidered smart object.

Threads of the Future: Biological Interfaces and AI Collaboration

Looking forward, the convergence of embroidery with biotechnology presents mind-bending possibilities. Research published in journals like Advanced Materials explores using embroidery techniques to create scaffolds for tissue engineering, stitching biocompatible threads in precise, three-dimensional patterns that guide cell growth. We might one day “embroider” living skin grafts or vascular networks, using the stitch as a guide for biology itself. This bridges the gap between textile and tissue, suggesting a future where medical implants are custom-grown on embroidered frameworks.

Furthermore, as machine learning and generative design software become more sophisticated, we are seeing the rise of AI-assisted embroidery design. An algorithm can be tasked with generating optimal stitch patterns for a desired function—be it maximum conductivity for a circuit, specific load distribution for a composite material, or a data-encoding pattern that is also aesthetically beautiful. This doesn’t remove the designer but augments them, offering solutions a human might not conceive of, based on simulations of physical properties. The artisan then curates and refines these digital proposals, creating a powerful synergy between human creativity and computational power.

The journey of a single stitch has traversed millennia, from securing animal hides to encoding quantum information. It has told stories of love and loss, signified social status, and now, carries data and conducts electricity. This enduring versatility is its greatest strength. Embroidery reminds us that the divide between art and science, between the analog and the digital, is a false one. In the loop of every stitch, there is both a connection to the past and a conductive pathway to the future, proving that the most profound innovations are often those that reimagine the tools we already have in our hands. The thread continues to spin forward, weaving a narrative where technology is soft, heritage is active, and intelligence is beautifully, intricately stitched.

You may also like

Guangxi Zhuang Brocade Handmade Tote – Ethnic Boho Large-Capacity Shoulder Bag

Original price was: $172.00.$150.00Current price is: $150.00. Add to cartHandwoven Zhuang Brocade Tote Bag – Large-Capacity Boho Shoulder Bag

Original price was: $178.00.$154.00Current price is: $154.00. Add to cartAncient Craftsmanship & ICH Herbal Beads Bracelet with Yellow Citrine & Silver Filigree Cloud-Patterned Luck-Boosting Beads

Original price was: $128.00.$89.00Current price is: $89.00. Add to cartAladdin’s Lamp Heat-Change Purple Clay Tea Pot

Original price was: $108.00.$78.00Current price is: $78.00. Add to cartAncient Craft Herbal Scented Bead Bracelet with Gold Rutile Quartz, Paired with Sterling Silver (925) Hook Earrings

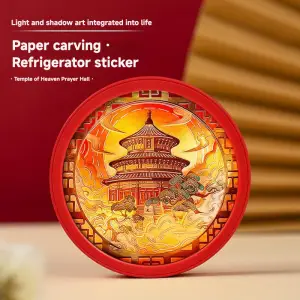

Original price was: $322.00.$198.00Current price is: $198.00. Add to cartThe Palace Museum Paper-Cut Light Art Fridge Magnets: Chinese Cultural Style Creative Gift Series

Price range: $27.00 through $36.00 Select options This product has multiple variants. The options may be chosen on the product page