In a Milan design studio, architects are specifying rattan not for outdoor furniture but for structural ceiling elements. Meanwhile, a Tokyo engineering firm tests bamboo composites for earthquake-resistant building panels. These aren’t isolated experiments—they signal a fundamental shift in how we perceive and utilize these ancient materials. Across construction sites, manufacturing facilities, and research labs worldwide, rattan and bamboo are transitioning from traditional crafts to cutting-edge solutions, driven by a renewed appreciation for their inherent strengths and sustainability credentials.

Material Intelligence Rediscovered

Rattan and bamboo are undergoing what materials scientists call ‘performance reevaluation.’ Where once they were valued primarily for aesthetics or tradition, now their mechanical properties are being quantified and optimized. Rattan’s tensile strength—approximately 100 MPa—compares favorably with many industrial materials while remaining renewable. Bamboo’s compressive strength rivals concrete in certain applications, yet it grows three feet in a single day under optimal conditions. This rapid growth cycle makes it one of the most renewable building resources available, with some species maturing in just three to five years compared to decades for traditional timber.

Manufacturers in Southeast Asia are developing hybrid processing methods that preserve natural flexibility while enhancing durability. One Vietnamese facility now produces rattan panels treated with plant-based resins that withstand humidity fluctuations far better than synthetic alternatives. The result isn’t just another ‘eco-friendly’ product but a technically superior material solving specific engineering challenges. A construction manager in Ho Chi Minh City shared how switching to these panels eliminated moisture-related expansion issues that had plagued previous projects: “We’d constantly be dealing with warping and gaps with conventional materials. The rattan composite maintains dimensional stability even during monsoon season, saving us both time and material waste.”

The scientific community is backing these practical observations with rigorous testing. According to research published in Construction and Building Materials, bamboo’s strength-to-weight ratio exceeds that of many steels, while its natural fibers provide exceptional fracture resistance. These properties make it particularly valuable in seismic zones, where flexibility can mean the difference between structural survival and collapse.

Architectural Integration Beyond Surface Treatment

The most significant trend involves moving beyond decorative applications to structural integration. In Bali, a recently completed community center features load-bearing bamboo arches spanning 15 meters without steel reinforcement. The design emerged from computational modeling that optimized the natural curvature of each bamboo culm, creating what the architect calls ‘biological engineering.’ This approach respects the material’s natural properties rather than forcing it to conform to conventional building paradigms.

Similarly, rattan is appearing in unexpected structural roles. A Berlin-based design collective recently completed an installation where tensioned rattan cables support glass panels in a courtyard canopy. ‘We’re not using rattan as decoration but as a functional structural element,’ explains lead designer Anika Vogel. ‘Its natural flexibility actually makes it more resilient to wind loads than rigid alternatives. During a recent storm that damaged several metal structures in the area, our rattan-supported canopy swayed gracefully without sustaining any damage.’

We spoke with materials researcher Dr. Kenji Tanaka, who noted: ‘The most exciting developments aren’t about making bamboo and rattan imitate other materials. We’re discovering what they can do that synthetics cannot. Bamboo’s hollow structure, for instance, provides natural insulation and acoustic damping that solid materials struggle to match. In our testing, bamboo composite walls reduced noise transmission by 40% compared to drywall of equivalent thickness.’ This inherent sound-dampening quality makes bamboo particularly valuable in urban environments and multi-unit housing where noise control significantly impacts quality of life.

Modern Manufacturing Meets Traditional Craft

The transformation of rattan and bamboo isn’t limited to laboratory settings. Traditional artisans are collaborating with engineers to develop production methods that scale ancient wisdom for contemporary needs. In the Philippines, a cooperative of rattan weavers has partnered with a technical university to create standardized structural components while maintaining their distinctive weaving patterns. The resulting products combine mathematical precision with artistic expression, demonstrating that mass production need not erase cultural heritage.

Bamboo processing has seen similar innovations. Where traditional treatment involved smoking or soaking in running water, modern facilities use controlled thermal modification to enhance durability without chemical preservatives. This process, known as thermowood treatment, stabilizes the material against insects and decay while maintaining its environmental benefits. A factory manager in China explained the evolution: “My grandfather taught me how to treat bamboo using traditional methods that took weeks. Now we achieve better results in hours through precise temperature control, but we still honor the principle of working with the material’s nature rather than against it.”

The World Health Organization has highlighted the health benefits of natural building materials like bamboo, noting their ability to regulate indoor humidity and reduce volatile organic compounds commonly found in synthetic alternatives. This creates healthier living environments while reducing energy consumption for climate control.

Practical Applications and Implementation Tips

For architects and builders considering rattan and bamboo, several practical considerations can ensure successful integration. First, understand the material’s relationship with moisture—both materials perform best when proper vapor barriers are incorporated in designs. Second, work with suppliers who provide properly graded materials, as natural variations require careful sorting for structural applications. Third, consider hybrid approaches that combine rattan or bamboo with complementary materials rather than attempting to replace entire systems at once.

A residential developer in California shared their gradual implementation strategy: “We started using bamboo for interior non-load-bearing partitions to gain experience with the material. After seeing how well it performed, we progressed to exterior screens and are now planning our first fully bamboo-supported structure. This stepped approach built confidence among our team and clients while allowing us to refine our techniques.”

For smaller-scale projects, rattan offers unique opportunities. Its flexibility makes it ideal for curved elements that would require complex fabrication in other materials. A furniture designer in London has built a successful practice around custom rattan pieces that combine traditional weaving with digital fabrication. “Clients are often surprised when I explain that their elegantly curved chair back is actually an engineered structural element, not just a decorative surface. The rattan provides both the form and the function.”

Sustainability and Economic Impact

The environmental advantages of rattan and bamboo extend beyond their renewable nature. Both materials sequester significant amounts of carbon during growth, with bamboo forests storing more carbon per hectare than many tree species according to UNESCO’s research on sustainable materials. This carbon capture continues in building applications, creating structures that effectively serve as carbon sinks throughout their lifespan.

Economic benefits are equally compelling. Rattan cultivation provides income for rural communities across Southeast Asia, while requiring minimal chemical inputs or irrigation. The material’s light weight reduces transportation energy compared to conventional building materials, and its natural abundance keeps costs predictable. Statista data shows the global bamboo product market growing at 5.3% annually, driven by both environmental concerns and performance characteristics.

In Colombia, a social enterprise has created a circular economy model around bamboo construction. They train local farmers in sustainable cultivation, employ community members in processing facilities, and use the material for affordable housing projects. The director explains the ripple effects: “Beyond creating jobs, we’re addressing the housing deficit with locally sourced materials that keep resources within the community. Families who previously couldn’t afford quality housing are now living in beautiful, durable homes that cost 30% less than conventional alternatives.”

Future Directions and Innovation

The potential applications for rattan and bamboo continue to expand as research deepens. Scientists are exploring bamboo-based composites for 3D printing construction elements, potentially revolutionizing how buildings are fabricated. Meanwhile, rattan’s cellular structure is being studied for inspiration in creating synthetic materials with similar strength-to-weight characteristics.

In earthquake-prone regions, bamboo’s flexibility is being harnessed in new ways. Japanese engineers have developed bamboo-reinforced concrete that maintains structural integrity through multiple seismic events. The bamboo fibers create what researchers call a “graceful failure mode”—the material bends and cracks in controlled ways that maintain life safety even as damage occurs. This contrasts with sudden brittle failures common in conventional reinforced concrete.

As climate considerations increasingly influence building decisions, rattan and bamboo offer pathways to lower embodied carbon without compromising performance. Their renaissance represents not a return to primitive methods but an advancement toward truly intelligent material usage—where natural properties guide design decisions and sustainability becomes inherent rather than added. The Milan designers and Tokyo engineers experimenting with these materials today aren’t reviving the past so much as building a more resilient future.

Material Specifications and Technical Considerations

Understanding the technical properties of rattan and bamboo is crucial for effective implementation. Rattan vines, belonging to the palm family, exhibit remarkable tensile strength due to their long, continuous fibers. This makes them ideal for applications requiring flexibility and resistance to pulling forces. The material’s natural elasticity allows it to absorb impact energy, making it valuable in seismic regions and for safety-critical applications.

Bamboo’s structural advantages stem from its unique composition. The hollow, segmented culms create natural reinforcement similar to engineered I-beams, providing excellent strength with minimal weight. Different species offer varying characteristics—Moso bamboo from China reaches heights of 28 meters with culm diameters exceeding 15 centimeters, while Guadua bamboo from South America demonstrates exceptional density and hardness suitable for structural applications.

Proper harvesting and treatment protocols significantly impact material performance. Bamboo harvested during the dry season contains lower starch content, reducing susceptibility to insect infestation. Modern treatment facilities use pressurized systems to impregnate bamboo with natural preservatives, extending its lifespan to match or exceed conventional building materials. These technical advances have enabled bamboo to meet international building codes in numerous countries.

Cultural Heritage and Modern Adaptation

The revival of rattan and bamboo represents more than just technical innovation—it’s a reconciliation of traditional knowledge with contemporary needs. Across Southeast Asia, rattan weaving patterns that once defined regional cultural identity are now being documented and adapted for structural applications. In Indonesia, master weavers collaborate with engineers to translate traditional knotting techniques into mathematical models for standardized components.

Bamboo’s cultural significance spans continents, from Asian spiritual traditions to South American indigenous building methods. Modern architects are learning from these ancient practices while incorporating digital tools. A Brazilian architect described this synthesis: “We use parametric design software to optimize bamboo structures, but the fundamental principles come from indigenous knowledge about material behavior. The computer helps us scale this wisdom, but the wisdom itself is centuries old.”

This cultural-technical fusion creates buildings that are both globally relevant and locally rooted. A school in Thailand uses bamboo construction techniques adapted from traditional house building, but optimized for educational facilities. The result is a learning environment that connects students to their cultural heritage while providing modern amenities and meeting international safety standards.

Implementation Challenges and Solutions

Despite their advantages, rattan and bamboo present unique challenges that require thoughtful solutions. Standardization remains a concern, as natural materials exhibit greater variation than manufactured alternatives. Leading producers address this through rigorous grading systems and statistical quality control. The International Bamboo and Rattan Organization has developed classification standards that help ensure consistent performance across batches.

Moisture management requires careful attention in design and construction. Both materials expand and contract with humidity changes, though modern treatment methods significantly reduce this movement. Successful projects incorporate design features that accommodate natural movement while maintaining structural integrity. Expansion joints, proper ventilation, and moisture barriers become critical considerations in humid climates.

Education and skills development represent another challenge. As these materials gain popularity, the need for trained craftspeople and installers grows. Vocational training programs are emerging worldwide, combining traditional craftsmanship with modern engineering principles. A training center in Costa Rica has certified over 500 bamboo builders in the past three years, creating new career paths while supporting sustainable construction.

Global Market Trends and Opportunities

The global market for rattan and bamboo products reflects growing recognition of their value. According to recent analysis, the bamboo construction market alone is projected to reach $98.3 billion by 2027, driven by sustainable building initiatives and performance advantages. Rattan furniture and architectural elements show similar growth, particularly in markets valuing both aesthetics and environmental responsibility.

Emerging applications continue to expand market opportunities. Bamboo-based textiles represent a rapidly growing segment, with fabrics offering natural antimicrobial properties and superior breathability. Rattan finds new life in automotive interiors, where its light weight and aesthetic appeal align with vehicle lightweighting initiatives and consumer demand for natural materials.

Investment in rattan and bamboo value chains creates economic opportunities across development spectrums. From smallholder farmers in tropical regions to advanced manufacturing facilities in industrialized nations, these materials support diverse business models. A European architectural firm recently established a rattan processing facility in partnership with Vietnamese growers, creating jobs while ensuring material traceability and quality control.

Environmental Impact and Lifecycle Analysis

Comprehensive lifecycle assessments reveal the full environmental benefits of rattan and bamboo. Compared to steel production, which generates approximately 1.8 tons of CO2 per ton of material, bamboo sequesters carbon throughout its growth cycle. A mature bamboo grove can capture up to 17 tons of carbon per hectare annually, making bamboo construction effectively carbon-negative when properly managed.

Rattan cultivation supports biodiversity conservation when harvested sustainably. The climbing vines grow within existing forests rather than replacing them, maintaining habitat complexity while providing economic value. This contrasts with monoculture plantations that often displace native ecosystems. Sustainable rattan harvesting has become a conservation strategy in several Southeast Asian protected areas.

End-of-life considerations further enhance these materials’ environmental profile. Both rattan and bamboo are fully biodegradable, returning nutrients to the soil rather than creating landfill waste. At the same time, their durability ensures long service lives when properly maintained. This combination of longevity and compostability creates a circular material flow rare in contemporary construction.

Innovative Applications and Research Frontiers

Current research pushes the boundaries of what’s possible with rattan and bamboo. Materials scientists are developing bamboo-based composites that match the performance of fiberglass while remaining fully biodegradable. These advanced materials show promise in automotive components, wind turbine blades, and other applications requiring high strength-to-weight ratios.

Rattan’s cellular structure inspires biomimetic design across multiple disciplines. Researchers study its efficient fiber distribution to improve synthetic composite materials. The same principles that make rattan resistant to cracking under stress inform new approaches to impact-resistant materials for protective equipment and transportation safety.

Nanotechnology opens additional possibilities. Bamboo-derived nanocellulose demonstrates remarkable properties for medical applications, including wound dressings and drug delivery systems. Meanwhile, rattan-based activated carbon shows promise for water purification, leveraging the material’s natural porosity for filtration applications.

These innovations demonstrate how traditional materials can drive cutting-edge technology. The same qualities that made rattan and bamboo valuable for centuries—strength, flexibility, and renewability—now position them at the forefront of material science. As research continues, these ancient materials will likely find applications we can scarcely imagine today, continuing their journey from traditional craft to technological marvel.

You may also like

Guangxi Zhuang Brocade Handmade Tote – Ethnic Boho Large-Capacity Shoulder Bag

Original price was: $172.00.$150.00Current price is: $150.00. Add to cartHandwoven Zhuang Brocade Tote Bag – Large-Capacity Boho Shoulder Bag

Original price was: $178.00.$154.00Current price is: $154.00. Add to cartAncient Craftsmanship & ICH Herbal Beads Bracelet with Yellow Citrine & Silver Filigree Cloud-Patterned Luck-Boosting Beads

Original price was: $128.00.$89.00Current price is: $89.00. Add to cartAladdin’s Lamp Heat-Change Purple Clay Tea Pot

Original price was: $108.00.$78.00Current price is: $78.00. Add to cartAncient Craft Herbal Scented Bead Bracelet with Gold Rutile Quartz, Paired with Sterling Silver (925) Hook Earrings

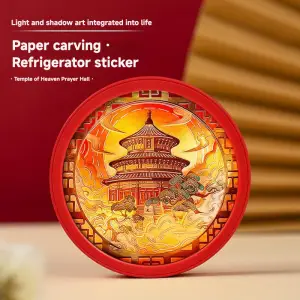

Original price was: $322.00.$198.00Current price is: $198.00. Add to cartThe Palace Museum Paper-Cut Light Art Fridge Magnets: Chinese Cultural Style Creative Gift Series

Price range: $27.00 through $36.00 Select options This product has multiple variants. The options may be chosen on the product page