In Jingdezhen, history is not confined to museum cases or history books; it lives in the creases of a potter’s hands, in the fine white dust that settles on every surface, and in the quiet, focused silence of a workshop at dawn. For over a millennium, this city has been synonymous with porcelain, its very name a metonym for the finest ceramic art. Known globally as the “Porcelain Capital,” its very earth seems imbued with a creative spirit. The story of Jingdezhen ceramics is one of continuity and fracture, of reverence and revolution, all baked in the intense heat of the kiln. It is told not only through legendary vases but through the individuals—the masters, the innovators, the collectors, and the young rebels—who give the clay its voice.

artisan's hands carefully shaping wet clay on a potter's wheel in a Jingdezhen workshop." loading="lazy" />

artisan's hands carefully shaping wet clay on a potter's wheel in a Jingdezhen workshop." loading="lazy" />The Kiln of History: A Millennium in the Making

The ascent of Jingdezhen was not an accident but a perfect alchemy of geography and human ingenuity. Nestled in the humid, subtropical hills of Jiangxi province, the region possessed the essential elements, often called the “four great treasures”: a unique, fine-grained white clay known as kaolin; petuntse, a feldspathic rock that acts as a flux and provides strength; dense forests to fuel the massive kilns; and a network of rivers like the Chang for transport and trade. While the area produced pottery for centuries, it was during the Song Dynasty (960–1279 AD) that Jingdezhen truly crystallized as a center of excellence. Its qingbai (shadowy blue) ware, so thin and translucent it was poetically compared to jade, set a new standard. The city’s destiny was formally sealed in 1004 AD when Emperor Zhenzong decreed that imperial porcelain would bear the mark “Made in the Jingde Reign,” forever wedding the city’s identity to the pinnacle of the craft.

The following dynasties—Yuan, Ming, and Qing—were eras of relentless technical and artistic innovation. The 14th century saw the perfection of underglaze cobalt blue decoration. This technique, often incorporating motifs inspired by Islamic art brought along the Silk Road, created the iconic blue-and-white porcelain that captivated the world. Later, the development of overglaze enamel families—the vibrant famille rose, famille verte, and others—added a painterly, polychrome brilliance. The scale of production was matched by engineering marvels. The development of “dragon kilns” snaking up hillsides and the more efficient, egg-shaped zhenyao kilns allowed for controlled firings exceeding 1300°C, producing porcelain of unmatched whiteness and durability. This was a colossal, state-sponsored industry, with the Forbidden City as its most prestigious client. As noted in its UNESCO World Heritage tentative listing, the “Jingdezhen Porcelain Industry Heritage” represents a sustained, unparalleled output that shaped global trade and aesthetic tastes for centuries, creating what scholars term the first truly global commodity.

The Master’s Touch: Preserving the Pulse of Tradition

In a small, sun-drenched studio in the old Sculpture Factory compound, the weight of this history rests in the steady hands of master carver Li Jian. Now in his seventies, he applies a handmade steel graver to a bone-dry vase with the precision of a surgeon. His knowledge encompasses the intricate floral patterns of the Ming and the dense, symbolic landscapes of the Qing. For Li, the craft is a profound dialogue with the past. “When I carve a dragon’s scale,” he says, his voice barely above a whisper as porcelain dust drifts in a sunbeam, “I am not just following a pattern. I am asking the clay to remember the hand of the artisan who first defined this form for an emperor. The pressure, the angle, the slight tremor—these are the things that books do not record.”

His work is an exercise in sublime patience; a single medium-sized vase can consume three months. He has trained only two apprentices in the last decade. “One must have the patience of the kiln itself,” he remarks. Masters like Li represent the living, embodied archive of Jingdezhen. Their skill is tacit knowledge, transmitted through years of silent observation and guided practice. They understand that the clay must be wedged to a specific consistency to avoid catastrophic hidden air bubbles, that the thickness of a glaze application will transform its final color, and that the kiln’s cooling rate can mean the difference between a piece that rings with a clear chime and one that emits a dull thud. This deep, tactile wisdom is the non-negotiable bedrock. It is a lineage under pressure, however, as the physical toll of the craft and the economic lure of China’s megacities make such disciplined apprenticeships a rarer choice.

The Studio of Second Chances: Writing a New Grammar

A fifteen-minute drive away, in a repurposed brick warehouse, a different energy hums. This is the studio of Xu Fan, a ceramist in her late thirties who returned to Jingdezhen after a decade as a graphic designer in Shanghai. Her work is a conscious, elegant fracture from pure tradition. She uses the city’s iconic kaolin and classic glazes but assembles them into abstract, architectural forms that resemble fragments of a futuristic cityscape. “Jingdezhen taught me the grammar of porcelain,” Xu explains, gesturing to a shelved piece that looks like a frozen, glazed ribbon. “But I wanted to write a new sentence.”

Her process embraces calculated risk. She often deliberately stresses the clay during firing, encouraging cracks and warps that a traditional master would deem failures. For her, these “flaws” are a record of the material’s struggle and resilience, a philosophy echoing wabi-sabi. She is not alone. Her small collective shares kiln space and critiques, creating a micro-economy of mutual support that attracts other returnees and international artists. This new wave is fueled by a global resurgence in craft and a desire for authentic, narrative-driven objects, a trend reflected in market analyses of the modern luxury sector. They are not rejecting heritage but engaging in a confident, critical conversation with it, using porcelain to explore contemporary themes of materiality, sustainability, and personal identity.

Practical Insight: Engaging with the Modern Ceramic Scene

For enthusiasts drawn to this contemporary energy, engaging requires a shift in perspective. Move beyond valuing only perfect replication. Seek out artist co-ops and open studios in areas like the Sculpture Factory, Sanbao International Ceramic Art Village, or the vibrant Taoxichuan (Ceramic Industrial Avenue) complex. When evaluating a piece, ask about the artist’s intent. What concept drives the form or surface treatment? How does it engage with Jingdezhen’s history? A warped vessel might be a meditation on impermanence; a rough, unglazed section may highlight the tactile truth of the clay itself. Building a relationship with a working studio, perhaps through an artist residency or workshop, offers a deeper, more meaningful understanding than any passive museum visit.

A Fragment of Dialogue: The Collector of Memory

Amidst these narratives of past and future sits Zhang Wei, whose life embodies the city’s layered, tangible history. Now eighty-two, he spent forty years as a kiln worker at a state-owned factory. His modest home is not a gallery of masterpieces but an archive of fragments—sherds of celadon, underfired test tiles, a single perfect lotus petal from a broken vase. “People see the masterpiece that leaves the kiln,” he says, offering tea in a simple, handleless cup he threw himself. “I see the ten that did not survive. This one,” he says, picking up a shard with a stunning, accidental crimson splash, “came from a firing in 1978. The temperature was wrong, the atmosphere was wrong. It was a ‘failure’ they were going to grind up. But look at this color! It has never been replicated.”

For Zhang, these fragments are the honest diary of the craft. Each holds a story of hope, error, and unpredictable beauty, meticulously cataloged in old candy tins. These “kiln wasters” are archaeological treasures, often revealing more about daily practice, problem-solving, and serendipitous discovery than any flawless museum piece ever could. They are a humble reminder that porcelain is a demanding alchemy of earth, water, fire, and air—a process never fully tamed by human will. As noted in studies of ceramic history, such fragments are invaluable for understanding the technological evolution and daily realities of historic kiln sites.

The Alchemy of Earth and Fire: The Process Unveiled

To fully appreciate the journey from Li Jian’s traditional carvings to Xu Fan’s abstract sculptures, one must understand the demanding, multi-stage pilgrimage from lump of clay to finished object. Each of the dozens of steps is a potential point of sublime success or heartbreaking failure.

It begins with the earth itself. Jingdezhen’s kaolin is refractory, requiring extreme heat to vitrify. After being dug, washed, and aged—sometimes for years to improve plasticity—it is thrown on the wheel or pressed into molds. A first, low-temperature “biscuit” firing around 800°C hardens the porous body. Decoration follows: painting with cobalt oxide under the glaze, intricate carving like Master Li’s, or applying overglaze enamels. The glaze, a secretive slurry of minerals, is then dipped, poured, or sprayed on. The final firing is the moment of truth. Pieces are carefully stacked in protective clay containers called saggars within the kiln. Over 24 hours or more, the temperature is meticulously raised to over 1300°C. The atmosphere inside—oxygen-rich (oxidizing) or oxygen-poor (reducing)—dramatically affects color outcomes; the legendary Qing dynasty “ox-blood” red, for instance, only manifests in a precise reducing environment. The kiln is then sealed and cooled slowly over days. The opening, or “unloading,” is a moment of profound vulnerability and anticipation known to every Jingdezhen potter across the centuries.

Practical Insight: Understanding Value and Authenticity

Navigating the world of Jingdezhen ceramics as a buyer requires informed discernment. For antiques, provenance and condition are paramount. Seek documentation and consider appraisal from a recognized expert. Reputable auction houses and specialized galleries offer more security than informal markets. For contemporary work, authenticity resides in the artist’s unique voice and command of technique. A genuine piece will often bear the subtle, beautiful marks of the hand—slight variations in glaze flow or form that are signatures, not defects. Be cautious of mass-produced items in tourist shops marketed as “handmade.” Purchasing directly from an artist’s studio or a respected gallery, many of which now have online presence, ensures your support nourishes the craft’s living ecosystem.

Sustaining the Flame: The Clay’s Adaptive Future

The path forward for Jingdezhen ceramics is one of both challenge and remarkable adaptation. The issues are real: the physical demands of the craft, the economics of sustained apprenticeship, environmental considerations around clay sourcing and kiln emissions, and the delicate balance between preserving intangible cultural heritage and fostering artistic freedom, a core concern for organizations like UNESCO. Yet, the future is far from dim. The influx of artists like Xu Fan has generated a new international dynamism. Residency programs at places like the Jingdezhen Ceramic Institute attract global creators, fostering cross-pollination of ideas. Digital tools are being integrated, with artists using 3D modeling for complex forms and social media to build direct connections with a worldwide audience, a trend accelerating the craft’s visibility as reported by cultural industry observers.

The city is learning that its unparalleled heritage is not a cage but the most solid of foundations. The ultimate resilience of Jingdezhen lies in this adaptive spirit—the same spirit that centuries ago mastered cobalt blue and engineered the dragon kiln. It is found in the master’s steady hand, the reformer’s bold experiment, and the collector’s cherished fragment. Together, they ensure that the fine white dust settling in a workshop at dawn is not an end, but the fertile beginning of the next creation, ready once more to be shaped by fire and imagination.

You may also like

Ancient Craft Herbal Scented Bead Bracelet with Gold Rutile Quartz, Paired with Sterling Silver (925) Hook Earrings

Original price was: $322.00.$198.00Current price is: $198.00. Add to cartAladdin’s Lamp Heat-Change Purple Clay Tea Pot

Original price was: $108.00.$78.00Current price is: $78.00. Add to cartAncient Craftsmanship & ICH Herbal Beads Bracelet with Yellow Citrine & Silver Filigree Cloud-Patterned Luck-Boosting Beads

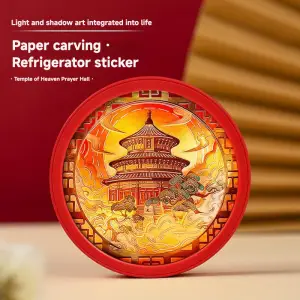

Original price was: $128.00.$89.00Current price is: $89.00. Add to cartThe Palace Museum Paper-Cut Light Art Fridge Magnets: Chinese Cultural Style Creative Gift Series

Price range: $27.00 through $36.00 Select options This product has multiple variants. The options may be chosen on the product pageHandwoven Zhuang Brocade Tote Bag – Large-Capacity Boho Shoulder Bag

Original price was: $178.00.$154.00Current price is: $154.00. Add to cartGuangxi Zhuang Brocade Handmade Tote – Ethnic Boho Large-Capacity Shoulder Bag

Original price was: $172.00.$150.00Current price is: $150.00. Add to cart