The quiet hum of a modern kiln in Jingdezhen bears little resemblance to the wood-fired roars of centuries past, yet the quest for the perfect surface continues with renewed urgency. Chinese porcelain, long viewed through the twin lenses of heritage and craftsmanship, is experiencing a subtle but profound recalibration. This is not a story of revival, but of recalibration—where material science meets digital aesthetics, and traditional forms encounter contemporary imperatives. The very definition of the craft is expanding, moving beyond the revered categories of Ming blue-and-white or Qing famille-rose to encompass objects that question the boundaries of the medium itself.

This transformation is driven by a new generation of makers, collectors, and curators who are not rejecting history but engaging with it as a dynamic toolkit. The global art market’s appetite for conceptual materiality, alongside China’s own cultural policy frameworks, has created fertile ground for experimentation. The result is a vibrant, sometimes challenging, new chapter where porcelain is as likely to be discussed in a materials science journal as in an art history text. This evolution speaks to a broader global trend where craft disciplines are being re-evaluated through technological and conceptual lenses, a phenomenon noted in cultural analyses from institutions like UNESCO, which emphasizes the dynamic nature of intangible cultural heritage.

The New Alchemists: Engineering the Ceramic Surface

For centuries, the magic of Chinese porcelain lay in its seemingly alchemical transformation through fire. Today, that alchemy is literal. The most radical innovations are occurring at the molecular level, fundamentally redefining what a ceramic surface can be and do. Laboratories within art academies and private studios have become crucibles for a new material science. Researchers at institutions like the China Academy of Art are pioneering reactive glazes that change color with ambient light or temperature—a sophisticated fusion of photochromic chemistry and ancient firing technique. These are not mere novelties; they create dynamic objects that interact with their environment, challenging the static permanence traditionally associated with porcelain.

This applied research has significant commercial and environmental implications. In Foshan, a major ceramic industrial hub, a collaboration between a design studio and a nanomaterials startup yielded a self-cleaning porcelain surface for architectural cladding. Infused with titanium dioxide nanoparticles, the coating uses photocatalytic reactions to break down organic pollutants, effectively repelling grime and contributing to improved urban air quality. This application boldly shifts porcelain from a decorative or domestic material into the realm of functional, sustainable urban infrastructure. The focus has decisively pivoted from solely replicating the past to actively engineering the future of the surface itself. As Dr. Li Yan, a chemist-turned-ceramicist, noted, “We are no longer just applying glaze; we are programming material behavior.” This new paradigm demands a hybrid artisan, fluent in both colloidal science and aesthetic theory.

Remarkably, these advancements often build upon a deep understanding of traditional principles. The ancient Chinese practice of yaobian, or kiln transformation—where unpredictable furnace effects create unique, celebrated glaze patterns—finds a profound modern parallel in controlled experiments with atmospheric firing and doped clay bodies. The serendipity of the wood kiln is being reverse-engineered, not to eliminate chance, but to understand and guide its potential, creating a dialogue between ancient unpredictability and modern precision.

The Digital Hand: Precision, Memory, and the Human Tremor

Technology’s role extends far beyond the chemistry lab into the very act of making. A central creative tension lies in the dialogue between digital precision and the embodied, tacit knowledge of the human hand. Artists are navigating this space with remarkable ingenuity, using technology not as a replacement, but as an extension of their intent.

“We asked our master painter to work from a digital file, a vector drawing of a neural network’s pattern. He said the brush couldn’t follow those lines. So we built a robotic arm that could hold his brush, guided by his hand’s pressure profile. The resulting piece, ‘Silicon Legacy,’ holds the tremor of human touch in every digital curve.” — Lin Wei, founder of SynthClay Studio, Guangzhou.

This anecdote encapsulates the contemporary ethos: collaboration between legacy and innovation. 3D scanning is routinely used to capture the intricate form of a decaying Song dynasty sherd, which then becomes the digital “seed” for a new, algorithmically grown vessel printed in fine porcelain slurry. Digital tools allow for the exploration of forms impossible to achieve on a wheel or by hand—intricate lattice structures inspired by bone growth, endlessly complex topological twists. Yet, the final object almost always requires the critical intervention of traditional skill. A master still must fettle the printed seams, judge the glaze thickness by eye and feel, and read the kiln’s atmosphere. The digital becomes a new kind of brush or tool, radically extending the artisan’s possibilities without severing the essential link to material intelligence.

The Invisible Infrastructure: Logistics in the Age of the Fragile Masterpiece

The global appetite for high-end contemporary porcelain, which is often large-scale, phenomenally delicate, and embedded with complex material innovations, demands a parallel revolution in handling and perception. The journey of a single, monumental installation piece from a Jingdezhen workshop to a museum in New York or a private gallery in Dubai is fraught with vibrational, climatic, and human risk. In response, a sophisticated niche sector of “cultural freight” logistics has emerged, becoming an invisible but critical part of the artwork’s story.

Specialized firms now employ sensor-laden, climate-controlled containers that monitor shock, tilt, humidity, and light exposure in real time, transmitting data streams directly to the artist, gallery, and collector. This hyper-documented journey becomes part of the artwork’s provenance—a digital certificate of authenticity written in gigabytes. The calculus is precise: the transport and insurance cost for one large, innovative vase can easily exceed $3,000 USD, a necessary premium for guaranteed integrity. This logistical evolution reflects a broader shift in the object’s lifecycle. From the synthesis of its engineered materials to its final, sensor-verified installation, contemporary porcelain exists within a continuous, monitored process. Its value is increasingly embedded in this documented chain of custody and its proven material innovation, as much as in any visual allusion to a dynastic past.

Curating New Narratives: From Historical Artifact to Contemporary Dialogue

The audience for this new porcelain is as globalized as its supply chain. While domestic collectors within China remain crucial, international interest has surged, with the global art pottery market seeing consistent growth. Major auction houses have expanded their contemporary design categories, featuring works by Chinese ceramic artists alongside established Western names. These pieces are collected not as ethnic artifacts, but as significant contributions to global contemporary art and design, a shift reflected in market analyses from firms like Statista tracking the rising value of contemporary craft.

The narrative in museums has shifted accordingly. Exhibitions no longer frame Chinese ceramics solely in a historical vacuum. A landmark exhibition at the Victoria and Albert Museum in London deliberately juxtaposed Tang dynasty tomb figures with 3D-printed ceramic sculptures, drawing direct lines between ancient conceptions of the spirit world and modern explorations of virtuality and form. This curatorial approach validates contemporary practice as a living, evolving tradition. Furthermore, the material innovations emerging from these studios often have significant downstream applications. Research published in journals like the Journal of the European Ceramic Society highlights how advanced porcelain composites developed for artistic purposes can inform technologies for biomedical implants, aerospace components, or sustainable building materials, blurring the line between craft and high-tech industry.

Practical Pathways: Engaging with the Recalibrated Craft

For artists, collectors, and enthusiasts navigating this evolving landscape, several actionable principles emerge. Success now requires a hybrid mindset and a willingness to engage with the craft’s expanded ecosystem.

For Makers & Artists:

- Pursue Hybrid Knowledge: Seek education beyond the pottery studio. A basic online course in material science, digital 3D modeling, or even coding can unlock entirely new creative avenues and collaborative opportunities.

- Document Relentlessly: Process is paramount. Maintain a detailed record of material recipes, firing data, digital files, and conceptual notes. This documentation is not just an archive; it’s a core part of the work’s value and narrative for galleries, collectors, and scholars.

- Seek Strategic Collaborations: Partner with materials scientists, programmers, or engineers. The most groundbreaking work often happens at the intersection of disciplines.

For Collectors & Enthusiasts:

- Develop New Literacies: Cultivate an eye and a mind that can appreciate both the historical reference and the intent behind a photocatalytic glaze or a data-driven form. Understanding the “how” and “why” deepens appreciation.

- Prioritize Documented Provenance: Inquire about more than just the artist and date. Ask for documentation of the process, material specifications, and even logistics reports. A well-documented piece carries a more robust and fascinating story.

- Engage Beyond the Market: Move past auction catalogs. Plan studio visits in centers like Jingdezhen, Foshan, or Yixing. Attend artist talks and follow the programs of contemporary ceramic art festivals, which offer direct insight into the current discourse.

A Universal Principle: Redefining Fragility

Finally, understand that the very concept of fragility has been redefined. It is no longer just about physical delicacy, but about the fragility of the ideas, data, and complex material states embedded within the object. Handling, displaying, and preserving these works requires an awareness of their entire technological and conceptual ecosystem. Consulting conservation guidelines from institutions like the World Health Organization on indoor air quality, for instance, could be relevant for maintaining a reactive glaze piece, just as ensuring digital files are archived is crucial for future understanding.

The recalibration of Chinese porcelain is a powerful testament to resilience and adaptation. It demonstrates how a craft burdened by millennia of glorious history finds liberation not by abandoning its past, but by reinterpreting its fundamental language—clay, glaze, fire—through the lenses of our present. The quiet hum in Jingdezhen now powers a global conversation, resonating in laboratories, digital studios, and museums worldwide, proving that the most enduring traditions are those brave enough to continuously transform.

You may also like

Guangxi Zhuang Brocade Handmade Tote – Ethnic Boho Large-Capacity Shoulder Bag

Original price was: $172.00.$150.00Current price is: $150.00. Add to cartBambooSoundBoost Portable Amplifier

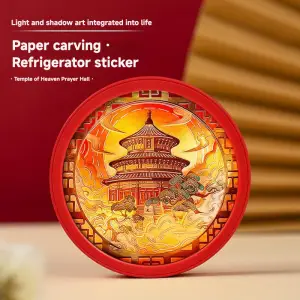

Original price was: $96.00.$66.00Current price is: $66.00. Add to cartThe Palace Museum Paper-Cut Light Art Fridge Magnets: Chinese Cultural Style Creative Gift Series

Price range: $27.00 through $36.00 Select options This product has multiple variants. The options may be chosen on the product pageAladdin’s Lamp Heat-Change Purple Clay Tea Pot

Original price was: $108.00.$78.00Current price is: $78.00. Add to cartAncient Craft Herbal Scented Bead Bracelet with Gold Rutile Quartz, Paired with Sterling Silver (925) Hook Earrings

Original price was: $322.00.$198.00Current price is: $198.00. Add to cartHandwoven Zhuang Brocade Tote Bag – Large-Capacity Boho Shoulder Bag

Original price was: $178.00.$154.00Current price is: $154.00. Add to cart