Along the forested hillsides of southern China, serpentine structures of brick and clay have slept for centuries. These are dragon kilns—longyao—their namesake evident in their sinuous forms climbing slopes like resting beasts. Their history begins not with a single inventor, but with gradual evolution during the Shang and Zhou dynasties, when potters discovered that building kilns along inclines created natural draught. By the Tang dynasty, these structures reached mature forms, some stretching over forty meters. They became the primary kilns for southern ceramic production, fueling regional economies and defining aesthetic traditions in provinces like Zhejiang, Fujian, and Guangdong for over a millennium. This was not merely a technological innovation; it was the birth of a landscape-altering craft that would shape culture, community, and commerce in profound ways.

Architecture as Cultural Expression

A dragon kiln is more than a furnace; it is a carefully calibrated environment where physics meets tradition, and architecture becomes an extension of the landscape. Built typically on hillsides with a 15 to 20-degree incline, the kiln’s elongated chamber allows heat to travel upward from the firing chamber at the bottom—the dragon’s head—to the chimney at the top—its tail. This ingenious design harnessed natural convection, creating a powerful updraft that required significantly less fuel than contemporary horizontal kilns. The thermal efficiency was a remarkable feat of early engineering, allowing for the high-temperature firings necessary for stoneware and porcelain.

The walls, constructed from refractory brick and clay tempered with rice husk or sand, could withstand temperatures exceeding 1300°C. This material choice was not arbitrary. Each kiln contained multiple stoking ports along its length, allowing attendants to feed the fire as it climbed, ensuring an even temperature gradient. The architecture reflected a deep, intuitive understanding of local materials and topography. In Jingdezhen, the porcelain capital, kiln builders utilized the region’s abundant porcelain stone and kaolin-rich clay not just for the pottery within, but for the kiln’s own structure, creating a remarkable unity of material purpose. The kiln itself was born from the very earth it would transform. This symbiotic relationship between structure and site is a hallmark of vernacular industrial design, a principle now studied for its sustainable logic.

The Social Anatomy of a Firing

Firing a dragon kiln was a communal ritual, a synchronized dance of fire and human skill, not merely an industrial process. It required a crew of eight to twelve workers, each with specific, hard-earned roles. The firemaster, a figure of immense respect, read the flame’s color and density through small observation ports. Stokers fed bundles of pine wood—the preferred fuel for its steady, clean heat and resinous aroma—into the ports. Sealers meticulously monitored and adjusted the clay plugs that controlled airflow. A typical firing was a marathon, lasting twenty to thirty hours, during which the kiln transformed into a living, breathing entity, its heat pulsating through the hillside.

The community often gathered, especially for the initial lighting, which sometimes included small offerings for a successful firing. This collective endeavor bound potters, laborers, and their families into a shared economic and cultural fate. The kiln’s output—whether the jade-like celadon of Longquan or the luminous “blanc de Chine” porcelain of Dehua—carried not just functional purpose, but the tangible imprint of this coordinated human effort. As historian Lu Ming notes, “The dragon kiln was a social hearth; its fire warmed the community’s livelihood.” The products were commodities, but the process was culture.

“My grandfather could tell the temperature within ten degrees Celsius just by listening to the fire’s roar and watching the smoke’s color. He said the kiln spoke—a low rumble at 800°C, a sharper whistle near 1250°C. We don’t fire the old dragon kiln monthly anymore, but when we do, for special commissions or festivals, the whole village remembers. The smell of pine smoke and hot clay is the smell of my childhood. It’s not nostalgia; it’s a physical memory in the air.”

Chen’s testimony underscores a sensory legacy, revealing how dragon kilns embedded themselves into local consciousness far beyond their economic function. This intimate knowledge, passed down through generations, represents a form of intangible cultural heritage, a living database of thermal acoustics and visual cues that modern digital pyrometers cannot replicate in spirit. It is a knowledge system recognized by bodies like UNESCO, which works to safeguard such traditional craft practices globally.

The Alchemy of Flame and Clay: Understanding the Results

What makes dragon kiln pottery so distinct? The answer lies in the journey of the flame. As the fire ascends the chamber over hours, it deposits a fine layer of wood ash on the ware. At peak temperatures, this ash melts into a natural glaze, creating surfaces that are complex, glassy, and often unpredictably beautiful—an effect known as “natural ash glazing.” The temperature gradient also means different parts of the kiln yield different results. Pieces near the fiery “head” might be darker and more heavily glazed, while those toward the “tail” could be paler and more muted.

This variability, once a challenge for standardization, is now celebrated. Each piece bears a direct record of its position in the kiln and the fire’s path. A vase might show a gradient of color, or a bowl might have a distinctive “kiln kiss” where it rested against another piece. These are not flaws but signatures of the process, highly prized by collectors. The high-temperature firing, often exceeding 1200°C, vitrifies the clay, making it non-porous and exceptionally durable. This functional aspect is significant; the World Health Organization has highlighted the importance of properly fired ceramic vessels for safe water storage and food preparation in various cultural contexts, as the process eliminates organic pathogens and creates a stable, inert surface.

Decline, Preservation, and Modern Revival

The 20th century brought profound change. Industrialization, the rise of electric and gas kilns, and shifting economic models made the labor-intensive dragon kiln increasingly obsolete for mass production. Many fell into disrepair, their brick skeletons reclaimed by vegetation. However, the story did not end there. A growing global appreciation for craft heritage, sustainable practices, and the unique aesthetic of wood-fired ware has sparked a significant revival.

Today, dragon kilns are experiencing a second life. They are valued not for efficiency, but for the unique, unpredictable effects they impart on clay—the ash glazing from pine fuel, the subtle variations in surface texture, and the deep, resonant colors unattainable in controlled electric environments. Artists and master potters now seek out restored kilns for special firings, embracing the collaborative ritual and the alchemical results. In places like the Nixing Pottery village in Qinzhou or the ancient kiln sites around Jingdezhen, firing a dragon kiln has become a cultural event, attracting students, tourists, and researchers eager to witness this ancient technology in action. This revival is part of a broader trend. While Statista reports the global ceramics market is driven by industrial manufacturing, a parallel and growing niche exists for artisanal, heritage-crafted goods, where story and process command value.

Practical Insights for Potters and Enthusiasts

For modern potters and ceramics enthusiasts drawn to the dragon kiln tradition, engagement can take many forms, from hands-on participation to thoughtful appreciation and support. The path involves respecting the tradition while adapting its lessons to contemporary practice.

Seek Out Immersive Workshops: The most direct way to understand the dragon kiln is through physical experience. Several cultural centers in China, such as those in Jingdezhen or Yixing, and increasingly in international craft schools, offer workshops where participants learn kiln stacking—a strategic process known as “setting” that affects airflow and ash deposition—and partake in the full firing cycle. This immersion reveals the physical demands, the necessary teamwork, and the irreplaceable intuition developed through direct contact with the fire.

Design for the Dragon’s Breath: If you have the opportunity to fire in a dragon kiln, approach your work as a collaboration with the flame. Use clay bodies and slips known to react beautifully with wood ash, such as those rich in iron or alumina. Experiment with form; shapes that allow ash to flow and pool can yield dramatic results. Crucially, employ test rings or tiles placed throughout the kiln to create a detailed map of temperature and ash effects. As contemporary ceramicist Zhang Hai reflects, “You curate the variables—clay, placement, form—but the final glaze is a gift from the fire. You learn to guide, not control.”

Document and Build a Personal Archive: Meticulous documentation is key. Before the firing, create a detailed diagram of the kiln setting. After unloading, cross-reference each piece’s final appearance with its location. Over multiple firings, this builds an invaluable personal database, transforming unpredictable alchemy into a more guided, though never fully tamed, dialogue with the process.

Support the Living Tradition: For those who may not fire a dragon kiln themselves, active support for its preservation is vital. Seek out and purchase work from artisans and studios dedicated to these methods. Plan visits to heritage sites like the Ancient Dragon Kiln in Yixing or the restored kilns in Dehua. Tourism and conscious consumerism provide tangible economic incentives for communities to maintain their physical kilns and, more importantly, transmit the associated knowledge to younger generations.

A Living Legacy in a Global Context

The dragon kiln’s narrative offers a powerful counterpoint to today’s disposable culture and hyper-controlled manufacturing. It represents a pre-industrial model of sustainable design that leveraged local topography for natural energy efficiency and utilized immediately available materials. It exemplifies a social model where craft was not an isolated artistic pursuit but a deeply integrated community activity, strengthening social bonds and shared identity.

The principles of the dragon kiln—harnessing natural forces, embracing material variability, and valuing collaborative process—resonate in contemporary studio pottery and the slow craft movement worldwide. From the slopes of Fujian to the studios of international artists inspired by its principles, the dragon kiln endures as a vibrant symbol. It teaches patience, deep respect for natural elements, and the profound beauty born of collaboration—between human intention and material resistance, individual skill and community effort, ancient tradition and modern innovation. The dragon may sleep longer between firings now, but when awakened, its flame continues to tell an ancient, essential story about making, meaning, and the enduring warmth of a shared fire. Its legacy is not locked in the past but is continually rekindled, offering timeless insights into the human relationship with earth, fire, and each other.

You may also like

Ancient Craftsmanship & ICH Herbal Beads Bracelet with Yellow Citrine & Silver Filigree Cloud-Patterned Luck-Boosting Beads

Original price was: $128.00.$89.00Current price is: $89.00. Add to cartAladdin’s Lamp Heat-Change Purple Clay Tea Pot

Original price was: $108.00.$78.00Current price is: $78.00. Add to cartBambooSoundBoost Portable Amplifier

Original price was: $96.00.$66.00Current price is: $66.00. Add to cartHandwoven Zhuang Brocade Tote Bag – Large-Capacity Boho Shoulder Bag

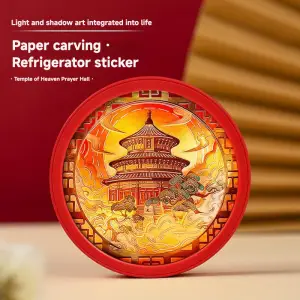

Original price was: $178.00.$154.00Current price is: $154.00. Add to cartThe Palace Museum Paper-Cut Light Art Fridge Magnets: Chinese Cultural Style Creative Gift Series

Price range: $27.00 through $36.00 Select options This product has multiple variants. The options may be chosen on the product pageAncient Craft Herbal Scented Bead Bracelet with Gold Rutile Quartz, Paired with Sterling Silver (925) Hook Earrings

Original price was: $322.00.$198.00Current price is: $198.00. Add to cart