At dawn, when the first wisps of smoke begin their slow climb from the dragon’s mouth, the transformation begins. This isn’t about romanticized tradition or artistic pilgrimage—it’s about heat management, clay chemistry, and the practical alchemy that turns earth into enduring vessel. The dragon kiln, with its serpentine form climbing a hillside, represents one of pottery’s most efficient thermal systems, perfected over centuries not for spectacle but for results. Its long, tunnel-like body is a masterpiece of passive engineering, a tool born from the relentless pursuit of consistency and quality in an inherently variable process.

The Kiln as a Working Tool: Anatomy of Efficiency

Forget the mystical metaphors. A dragon kiln is essentially a long, inclined tunnel—typically 10 to 40 meters—built into a slope. This fundamental design solves one of ceramics’ oldest practical problems: uneven heat. The slope creates a natural draft, known as the stack effect, pulling flames and hot air from the firebox at the dragon’s ‘head’ up through the chamber where pottery rests. This results in a predictable temperature gradient, increasing gradually along the length. Potters exploit this gradient with strategic placement, turning a potential flaw into a powerful feature. High-fire stoneware requiring 1280°C is positioned near the fiery head, while earthenware needing 1000°C finds its place further back. A single firing can thus accommodate multiple clay bodies and glazes simultaneously—a feat of batch efficiency that modern, compartmentalized electric kilns struggle to match.

The internal architecture is equally pragmatic. Each piece rests on refractory shelves, separated by small clay tripods called spurs or stilts that leave only minimal marks. Loading the chamber is a three-dimensional puzzle of airflow management. Every pot must be positioned to allow flame and heat to wash over it freely. Too tight a pack, and reduction atmospheres develop unpredictably, starving glazes of oxygen; too loose, and precious heat escapes unused, wasting fuel. Experienced potters develop an intuitive sense for this spacing, knowing that a difference of mere centimeters can alter how the flame licks a glaze, affecting its final color and texture. This knowledge is rarely codified in textbooks; it is passed down through shared kiln loadings, silent observation, and hands-on correction.

Managing the Climbing Flame: The Firekeeper’s Art

Firing a dragon kiln is an exercise in dynamic response, demanding constant, nuanced attention. Unlike a programmable electric kiln, this living system responds to ambient humidity, wood moisture content, wind direction, and even barometric pressure. The firekeeper, often working in grueling shifts during a 24 to 48-hour firing, becomes a reader of subtle signs. Orange flames licking from spy holes indicate a temperature around 900°C; a clear, roaring sound signifies strong draft and efficient combustion. Wood is added not on a rigid schedule, but in response to this real-time sensory feedback—a dance with the fire.

Practical challenges are constant. If the temperature plateaus, the firekeeper might open a lower stoke hole to increase oxygen influx. If ash begins to vitrify and risk fusing to pots at extreme temperatures, the firing rate must be carefully modulated. Every decision is a multi-variable equation: achieving target temperatures, maintaining specific atmospheric conditions (reduction or oxidation) for desired glaze effects, and conserving substantial amounts of fuel. A typical 15-meter kiln can consume 3 to 5 cords of pine during a full firing. The choice of wood is itself practical; pine’s resinous nature produces ash that, when carried by the flame, can settle on unglazed ware and melt into a subtle, natural glaze—a serendipitous bonus the kiln’s design actively promotes.

A Potter’s Empirical Logbook

Chen Li, who fires a 22-meter dragon kiln in Jiangxi province quarterly, describes the process in decidedly unromantic terms. “People visit and see ‘ancient tradition.’ I see thermodynamics and continuous problem-solving,” she states. “Last November, the wind shifted unexpectedly. We had to quickly block two upper spy holes with spare bricks and switch to splitting wood into smaller pieces for faster, hotter combustion. It wasn’t about preserving heritage in that moment—it was the practical race to save 40 pieces from under-firing.”

Her approach is rigorously empirical. “We keep a detailed log with simple symbols: circles for successful glaze results, crosses for cracks or flaws. After a dozen firings, patterns become undeniable data. We learned that our celadon glazes thrive in the kiln’s middle third, not because of old sayings, but because our logs show 23 successful pieces there versus only 4 elsewhere.” This data-driven mindset extends to maintenance. After each cooling, her team spends days inspecting the brick lining for heat-leaking cracks, repairing them with a homemade refractory mortar of local clay, sand, and rice husk ash. “Every kiln has its personality,” Chen notes. “Ours has a slight bend at the 16-meter mark that creates a persistent hot spot. We used to fight it. Now we acknowledge it and use it deliberately for pieces that need an extra kick of heat.”

The Alchemy of Clay and Flame: Understanding the Transformation

The magic of the dragon kiln lies in what this precise control over a primal force makes possible. The firing process orchestrates two critical, irreversible chemical transformations in the clay. First, around 573°C, quartz particles within the clay undergo a sudden expansion. Later, between 900°C and 1280°C, vitrification occurs—the clay particles begin to fuse together into a strong, glassy matrix. The dragon kiln’s gradual temperature gradient allows these changes to happen more evenly, reducing the thermal shock that causes cracks and dunting.

Furthermore, the kiln is a master of atmosphere. By controlling the air intake at the firebox and stoke holes, potters can create a reduction atmosphere (oxygen-starved) or an oxidation atmosphere (oxygen-rich). This dramatically alters glaze outcomes. A copper-based glaze fired in oxidation will yield a green color, but the same glaze in reduction can turn a iconic oxblood red. The long chamber of the dragon kiln can naturally stage different atmospheric conditions, offering a spectrum of effects in one firing. As noted by UNESCO in its recognition of traditional ceramic crafts, this interplay of material, design, and skill forms an intangible cultural heritage rooted in deep scientific understanding.

The process is a dialogue between material and environment. A study in the Journal of the European Ceramic Society on traditional wood-firing noted that the fly ash from specific woods deposits complex mineral compounds on pottery surfaces, creating unique textures and color variations impossible to replicate with commercial glazes. This is not a flaw but a feature—the kiln’s environment becomes an active ingredient in the finish.

Practical Insights for the Modern Potter

While few have access to a full-scale dragon kiln, its principles offer valuable lessons for any ceramic artist seeking to deepen their practice.

- Embrace the Gradient: Even in a standard kiln, be mindful of hot and cool zones. Map your kiln’s personality by placing witness cones or temperature monitors in different shelves during firings. Use this map strategically, just as a dragon kiln user would, placing pieces according to their thermal needs.

- Log Everything: Follow Chen Li’s example. Maintain a simple firing log. Note clay body, glaze, placement in the kiln, firing schedule, and weather conditions. Over time, this transforms intuition into actionable knowledge, revealing patterns invisible in single batches.

- Respect the Materiality of Fuel: If you use a wood, gas, or soda kiln, understand how your fuel interacts with your work. Experiment with different woods or burner adjustments to see their effect on ash deposition and atmosphere, moving beyond just “setting the temperature.”

- Design for the Fire: When creating pieces, consider how they will interact with flame and airflow. Forms with deep recesses or tight lips may trap gases, leading to unpredictable results. Think of your work as a participant in the firing environment, not just a passive occupant.

Consider the experience of Miguel, a studio potter in New Mexico who adapted dragon kiln principles to his smaller anagama (a single-chamber, wood-fired kiln). “I started sketching my kiln loads, treating the path of the flame like a river,” he explains. “I place larger, plainer forms upstream to protect more delicate, glaze-rich pieces downstream from being buried in ash. It’s about directing energy, not just containing it.”

Beyond the Studio: Cultural and Economic Sustainability

The dragon kiln model extends its relevance beyond technical ceramics into the realms of cultural sustainability and local economics. In regions like Longquan in China or Tamba in Japan, community kilns fired a few times a year create a rhythm that binds artisans. The firing becomes a communal event, pooling resources, labor, and risk. This collaborative model lowers the barrier to entry for individual potters and fosters a living workshop environment where skills are exchanged in real time.

This system also promotes a circular, localized material economy. The kilns are often built from local clay and brick. Fuel is sourced from managed local woodlands. The very imperfections and variations celebrated in the finished wares—the ash deposits, the flashing from flame contact—tell the story of a specific place and time. According to market analyses from sources like Statista, consumer interest in authentic, artisan-made goods with a tangible provenance continues to grow, suggesting that the value of such profound craftsmanship is being rediscovered. The object becomes a document of its own making.

The Enduring Relevance in a Digital Age

In an era of digital precision and automated manufacturing, the dragon kiln stands as a powerful counterpoint. It represents not obsolete technology, but a sophisticated, low-tech system that achieves remarkable results through a symbiotic relationship with natural forces. Its efficiency is contextual and holistic, factoring in local materials, sustainable fuel sourcing (when managed properly), and unparalleled batch versatility.

The dragon kiln also teaches resilience and adaptation. As potter and researcher Jack Troy has observed, the kiln demands a collaboration with the elements, not a domination of them. This philosophy is increasingly relevant. The World Health Organization (WHO) has highlighted the mental health benefits of traditional, hands-on crafts, which engage the mind and body in focused, rhythmic work. The sustained attention required to tend a dragon kiln firing—a mix of vigilance, patience, and physical labor—is a form of deep practice that is both technically demanding and meditatively grounding. It cultivates a specific kind of focus that is eroded by constant digital interruption.

The wisps of smoke at dawn signal more than the start of a firing; they mark the continuation of a conversation between human ingenuity and elemental force. It is a conversation conducted in the language of heat, draft, and chemical change, yielding objects that are not merely made, but born of a specific, irreplicable journey through flame. The dragon kiln, in its majestic simplicity, proves that the most advanced tool is sometimes the one that best harnesses the wisdom of the world as it is, transforming raw earth into objects of timeless utility and beauty through the disciplined application of fire, patience, and learned truth.

You may also like

Handwoven Zhuang Brocade Tote Bag – Large-Capacity Boho Shoulder Bag

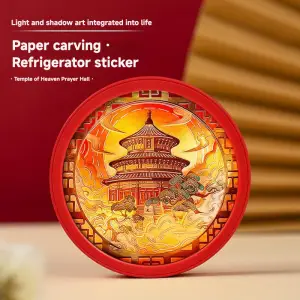

Original price was: $178.00.$154.00Current price is: $154.00. Add to cartThe Palace Museum Paper-Cut Light Art Fridge Magnets: Chinese Cultural Style Creative Gift Series

Price range: $27.00 through $36.00 Select options This product has multiple variants. The options may be chosen on the product pageBambooSoundBoost Portable Amplifier

Original price was: $96.00.$66.00Current price is: $66.00. Add to cartGuangxi Zhuang Brocade Handmade Tote – Ethnic Boho Large-Capacity Shoulder Bag

Original price was: $172.00.$150.00Current price is: $150.00. Add to cartAladdin’s Lamp Heat-Change Purple Clay Tea Pot

Original price was: $108.00.$78.00Current price is: $78.00. Add to cartAncient Craft Herbal Scented Bead Bracelet with Gold Rutile Quartz, Paired with Sterling Silver (925) Hook Earrings

Original price was: $322.00.$198.00Current price is: $198.00. Add to cart