Forget museum cases and auction catalogs for a moment. The true story of Chinese porcelain unfolds in kitchens, on tables, and in the hands of those who use it daily. This is a material born from necessity, refined through centuries of practical problem-solving. Its journey from a lump of earth to a treasured household object is a testament to human ingenuity, where every step was guided by a relentless focus on utility, resilience, and the subtle demands of daily life.

The Clay’s Journey: From Earth to Oven

It begins with a specific geology. True porcelain requires a marriage of two key materials: kaolin, a refractory white-firing clay that provides structure, and petuntse, a feldspathic rock that vitrifies into a glassy matrix at searing temperatures. This fusion, achieved in kilns exceeding 1300°C, creates a body that is white, resonant, and impervious to liquids. But for the potters of historic centers like Jingdezhen, the “Porcelain Capital,” theory was nothing without intimate, hands-on knowledge.

They learned through generations of trial and error that not all kaolin was equal. Different pits and hillsides yielded clays with subtle variations in plasticity, mineral content, and firing color. A batch from the north side of a mountain might possess the perfect elasticity for throwing exquisitely thin-walled cups, while clay from a southern deposit was better suited for the robust walls of a storage jar. This geologically informed curation was the first critical step. Before any wheel turned, the clay itself underwent a transformation. The process of wedging—systematically kneading the moist clay—was a vital, physical ritual. Its purpose was to expel every trace of air. A single hidden bubble, expanding violently in the kiln’s inferno, could cause a piece to shatter, rendering weeks of meticulous work into worthless fragments.

Throwing on the wheel demanded a physical intuition that transcended measurement. A master potter felt the story in the clay through their palms. The gentle resistance, the yielding pull, the growing height—all communicated the state of the forming wall. They knew precisely when it was thin enough to promise that magical, post-firing translucency yet thick enough to survive the thermal ordeal ahead. This tactile dialogue between craftsman and material was the foundation of every form.

Glazing introduced another layer of calculated risk, a complex chemistry made manifest. Take the celadon glaze, prized for centuries for its serene, jade-like color. Achieving that signature soft green-grey was not a matter of simple pigment. It required a precise amount of iron oxide in the glaze slurry and, crucially, a specific reducing atmosphere inside the kiln—an environment deliberately starved of oxygen. The potter had to control the kiln’s air intake with careful sealing and fuel management. Too little oxygen, and the piece would emerge dull, smoky, and spoiled. Too much, and the reducing reaction would fail, and the coveted celadon hue would vanish, leaving a plain, yellowish finish. These were high-stakes technical parameters, where artistic vision was inextricably linked to environmental control and chemical precision.

Designed for Duty: Form Meets Function

Consider the humble rice bowl, an object so commonplace its genius is often overlooked. Its classic form—a wide mouth, a subtly rounded body, and a distinct foot ring—is a masterpiece of ergonomics developed over a millennium. The raised foot ring serves multiple purposes: it prevents the user’s fingers from touching a potentially scorching base, it gives the bowl stability on flat surfaces, and it protects the delicate rim from chipping during handling. The curvature of the sides is designed to fit comfortably in the palm of one hand, while the wide mouth facilitates easy eating with chopsticks and simplifies cleaning. Every contour answers a question posed by daily use.

This principle of purposeful design extends to specialized vessels. The meiping, or “plum blossom vase,” is celebrated for its elegant, slender neck and broad shoulders. While often used decoratively today, its form was originally highly functional. Designed to hold a single, prized branch of flowering plum, the narrow neck restricted water evaporation, helping to keep the delicate bloom fresh for a longer period. It was a beautiful solution to a practical desire—to prolong the brief beauty of early spring.

Decoration, too, was frequently in service of utility. The ubiquitous blue-and-white patterns, painted with cobalt oxide before glazing, provided more than aesthetic pleasure. On the surface of a wet bowl or an oily plate, the painted patterns offered visual and slight tactile texture, improving grip. A well-painted scrolling vine along the curve of a teapot handle could guide the thumb naturally to the optimal holding position. Even the celebrated crackle glazes of Guan or Ge ware, once romanticized as “happy accidents,” were often the result of controlled technical mastery. Potters learned to exploit the different cooling rates and shrinkage coefficients of the clay body and the glaze to create a predictable network of fine cracks, adding a layer of visual depth and texture without compromising the vessel’s structural integrity.

“We test every new shape by using it for a month in our own home,” says Lin Wei, a sixth-generation potter in Dehua, famous for its blanc de Chine porcelain. “Does the teapot pour a clean stream without dripping? Does the lid of the soup tureen still fit snugly after fifty washes in hot water? Does the cup’s rim feel pleasant and thin against the lips? Beauty is an empty concept if the piece is awkward to use. If my wife complains about washing it, the design goes straight back to the wheel. Our work must earn its place in someone’s daily life.”

This deeply ingrained, user-centered philosophy logically extended to the economics of production. Potters standardized certain high-volume forms, like the cylindrical guan jar, not only for aesthetic consistency but because their uniform shapes allowed them to be stacked efficiently inside the kiln. This stacking, often using refractory clay separators, maximized the yield of each firing—a crucial consideration given the enormous cost and time involved in heating a massive kiln for days on end. It was a direct equation where form influenced manufacturability and cost. The famous “egg-shell” porcelain, with walls so thin they are semi-translucent, represents the apex of this technical drive. While impractical for rough daily use, its creation was a powerful demonstration of a workshop’s supreme skill—a tangible proof of concept that could attract the patronage of emperors and wealthy merchants, funding the more mundane production. Every curve, every measured thickness, and every glaze formula ultimately answered a direct question of use, durability, or efficient production.

The Kiln: A Week-Long Alchemy

The transformation of shaped, decorated clay into porcelain is an alchemical event, a days-long ritual of fire and control. The kiln, or yao, was not merely an oven but the heart of the workshop, a massive brick structure that consumed vast quantities of wood. A single firing could last five to seven days, requiring constant vigilance from a team of experienced kiln masters. They monitored the progression through small observation ports, judging temperature by the color of the flames—from initial orange to a searing, blinding white. Stoking had to be perfectly timed; a rush of air at the wrong moment could ruin an entire chamber’s worth of celadon ware by altering the atmospheric chemistry.

The placement of wares within the kiln, known as setting, was a strategic art. Pieces requiring the highest heat and purest conditions were placed near the center. Those with glazes tolerant of more variation, or sturdier utilitarian items, were positioned nearer the walls or the kiln’s mouth. The slow, controlled cooling period at the end of the firing was just as critical as the heating. Rapid cooling could cause catastrophic thermal shock, creating cracks or turning glaze into a network of shards. The kiln master’s knowledge, often passed down orally and guarded closely, was the final, indispensable link in the chain. As UNESCO notes in its documentation of Jingdezhen’s craftsmanship, the traditional kiln technologies represent “a unique accumulation of knowledge and practice,” a non-verbal science of heat management perfected over a thousand years.

Porcelain in Motion: Adaptation and Global Dialogue

The functionality of Chinese porcelain ensured its journey far beyond imperial courts. It traveled the Silk Road in camel caravans, packed in straw and rice chaff, prized by merchants and elites from Istanbul to Venice for its durability and hygiene compared to wood or porous earthenware. Its impervious surface was easier to clean and less likely to harbor bacteria, a practical advantage that aligned with emerging ideas of sanitation long before germ theory. But this was not a one-way street. As global trade exploded in the 16th century, particularly with the establishment of sea routes by Portuguese and later Dutch traders, Chinese potters began receiving specific orders from abroad.

This interaction sparked remarkable adaptations. Potters in Jingdezhen began producing precise replicas of German stoneware jugs, Spanish-style albarelos (pharmacy jars), and Portuguese wine coolers. They painted coats of arms for European aristocratic families, scenes from Dutch engravings, and even inscriptions in Latin or Arabic. A surviving example is a Chinese porcelain tankard from the late 17th century, perfectly mimicking the form of a European pewter mug but executed in brilliant blue-and-white. This was not mere copying; it was a sophisticated, client-driven manufacturing, proving the system’s flexibility. The form was foreign, but the material intelligence—the thinness of the walls, the stability of the glaze, the precision of the firing—was pure Chinese craftsmanship, applied to solve a new set of functional requirements from a global clientele.

The influence also flowed inward. The vibrant famille rose palette, incorporating shades of pink derived from colloidal gold, was developed in the 18th century partly in response to European enameling techniques and tastes. New shapes, like teapots and coffee pots suited to social rituals spreading from the West, were integrated into the repertoire. Porcelain became a medium of cross-cultural conversation, its fundamental practicality making it the perfect canvas for global exchange. This dialogue created a massive export economy; global trade data shows ceramics remain a multi-billion dollar industry today, a legacy built on centuries of adaptable craftsmanship.

The Unseen Qualities: Hygiene, Safety, and Material Science

Beyond shape and decoration, the intrinsic material properties of fired porcelain solved fundamental human concerns about health and safety. Its vitrified, glass-like surface is non-porous, preventing liquids and oils from seeping in. This made it inherently more hygienic than wood, leather, or low-fired pottery, which could harbor residues and bacteria. In an age before modern disinfectants, this was a critical advantage. Anecdotes from European courts in the 17th century often noted that royalty and nobility prized Chinese porcelain not only for its beauty but because it was believed—correctly—to be safer for food and drink, less likely to impart off-flavors or cause illness.

Modern material science confirms these empirical observations. Studies published in journals like Ceramics International have analyzed the microstructure of historic porcelain, finding that the high-temperature firing creates a dense network of mullite crystals within a glassy matrix. This structure gives porcelain its renowned strength and, crucially, its low porosity. Research into glaze chemistry has also shown how traditional lead-free glazes, like the ash glazes used in early celadons, created stable, inert surfaces perfect for food contact. This ancient knowledge of material safety resonates strongly today, as consumers and manufacturers alike seek out non-toxic, durable materials for tableware.

The thermal shock resistance of well-made porcelain is another unsung virtue. The careful balancing of clay and flux materials, along with controlled kiln cooling, resulted in a body that could withstand sudden temperature changes. This is why a fine porcelain teacup can endure the shock of near-boiling water without cracking—a property that cheaper earthenware lacks. This resilience translated directly to longevity in the household, making porcelain a wise investment. A service set could last generations, its practicality outweighing its initial cost.

The Modern Legacy: Practicality in a New Age

Today, the legacy of this practical tradition is multifaceted. In bustling Chinese households and restaurants worldwide, durable, modestly decorated porcelain remains the unchallenged champion for daily service—from steamers for dumplings to bowls for noodles. Its non-porous surface is food-safe, dishwasher-proof, and resilient, the direct descendant of the kiln-tested wares of centuries past. The global tableware market continues to be dominated by porcelain and its close relative, bone china, precisely because of these functional merits.

Simultaneously, contemporary designers and artists are re-engaging with this material intelligence. They are not just making art about porcelain but thinking with it, exploring its inherent functional properties. Studio potters experiment with clay bodies and glazes for specific thermal performance, creating mugs that keep coffee hot longer or plates that are safe from freezer to oven. Designers use digital tools to analyze the ergonomics of classic forms, refining them for modern grips and dishwashers. The ancient quest for the perfect rice bowl continues, informed by new tools but guided by the same core principle: how does this object feel and perform in human hands?

This revival is not merely nostalgic. It is a response to a growing desire for objects with integrity in an age of disposable goods. A young professional in Shanghai might seek out a hand-thrown porcelain coffee cup, not as a fragile ornament, but for the tangible daily pleasure of its weight, its heat retention, and the way its rim meets the lip. The value lies in its sustained performance, a direct line back to Lin Wei’s philosophy of a piece earning its place in daily life.

Research into the material science of historic porcelain continues to reveal the sophistication of old recipes and firing protocols. These studies often confirm what potters knew empirically: that certain clay mixtures yield exceptional mechanical strength, or that specific glaze formulations resist micro-crazing and bacterial growth exceptionally well. Modern industry seeks to learn from these ancient material solutions, looking to create more sustainable and durable products. The World Health Organization’s guidelines on food safety underscore the importance of non-porous, easily cleanable food-contact surfaces, a standard that high-quality porcelain has met for a millennium.

The story of Chinese porcelain, therefore, is not locked in a static past. It is a living narrative of problem-solving. From the potter wedging clay to remove fatal air bubbles, to the kiln master reading the fire’s color, to the artisan painting a cobalt pattern that also provides grip, every act was rooted in a deep understanding of material, process, and human need. It reminds us that the most enduring beauty is often that which works quietly, reliably, and perfectly in the everyday, a testament to the profound elegance of things that are simply, superbly, fit for purpose. In a world cluttered with objects of fleeting novelty, the quiet intelligence of a well-made porcelain vessel offers a different kind of luxury: the luxury of reliability, of a form shaped not by passing fashion, but by the enduring human hand.

You may also like

Handwoven Zhuang Brocade Tote Bag – Large-Capacity Boho Shoulder Bag

Original price was: $178.00.$154.00Current price is: $154.00. Add to cartAladdin’s Lamp Heat-Change Purple Clay Tea Pot

Original price was: $108.00.$78.00Current price is: $78.00. Add to cartAncient Craft Herbal Scented Bead Bracelet with Gold Rutile Quartz, Paired with Sterling Silver (925) Hook Earrings

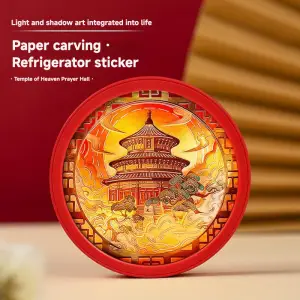

Original price was: $322.00.$198.00Current price is: $198.00. Add to cartThe Palace Museum Paper-Cut Light Art Fridge Magnets: Chinese Cultural Style Creative Gift Series

Price range: $27.00 through $36.00 Select options This product has multiple variants. The options may be chosen on the product pageAncient Craftsmanship & ICH Herbal Beads Bracelet with Yellow Citrine & Silver Filigree Cloud-Patterned Luck-Boosting Beads

Original price was: $128.00.$89.00Current price is: $89.00. Add to cartGuangxi Zhuang Brocade Handmade Tote – Ethnic Boho Large-Capacity Shoulder Bag

Original price was: $172.00.$150.00Current price is: $150.00. Add to cart