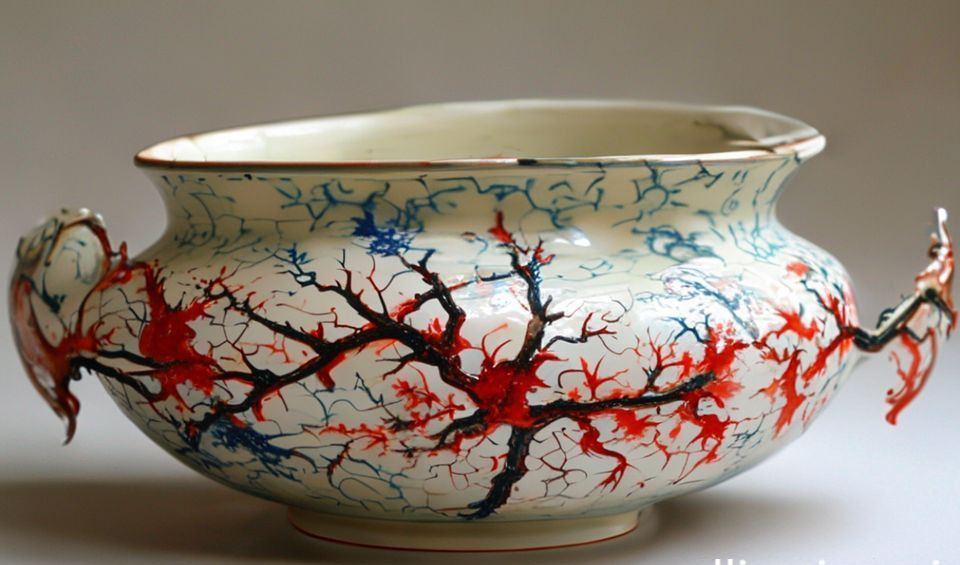

The first time you hear the subtle pinging of a crackle glaze cooling in the kiln, it sounds like porcelain whispering secrets. These tiny fractures aren’t accidents—they’re meticulously engineered networks that transform simple ceramics into objects of depth and character. For centuries, Chinese potters have harnessed this phenomenon not as a decorative afterthought, but as a fundamental surface treatment that balances visual intrigue with practical considerations. This ancient technique, where a web of fine lines etches itself into the glaze surface, represents a profound dialogue between control and surrender, between the potter’s hand and the material’s inherent nature.

The Historical Journey: From Imperfection to Imperial Treasure

The story of Chinese crackle glaze is one of aesthetic evolution, deeply intertwined with China’s ceramic history. While early instances of accidental cracking date back to the Shang dynasty, it was during the Song dynasty (960–1279 AD) that crackle was deliberately cultivated and elevated to an art form. This period, renowned for its refined and philosophical approach to the arts, saw crackle become a prized characteristic in the wares produced for the imperial court. The celebrated Ge (Brother) and Guan (Official) kilns produced pieces where the crackle pattern, known as “ice crackle” or “crab claw” crackle, was not a flaw but the very essence of the object’s beauty.

These patterns were thought to mirror the natural world—the fissures in ice, the veins on a leaf, or the cracks in ancient riverbeds—embodying the Song aesthetic of quiet elegance and harmony with nature. As noted by the Smithsonian’s Freer Gallery of Art, Song dynasty crackle wares remain some of the most revered and technically sophisticated ceramics in history, setting a standard that would influence generations. The tradition persisted and adapted through subsequent dynasties. The Ming and Qing periods saw crackle glazes used on a broader array of forms and sometimes combined with colorful enamels. While the Song ideal was often monochrome—celadon or white glaze with dark iron-stained cracks—later potters experimented with more vibrant backgrounds.

The technique never disappeared but ebbed and flowed in popularity, always retaining its association with classical refinement and technical mastery. Today, the legacy continues in studios across Jingdezhen, the centuries-old ceramic capital, and beyond, where contemporary artists reinterpret this ancient language of cracks for a modern audience. The global appreciation for these wares is reflected in their enduring presence in museum collections and their influence on ceramic practices worldwide, a testament to a cultural heritage that organizations like UNESCO work to preserve and promote.

The Science and Mechanics Behind the Magic

At its core, crackle occurs due to a calculated mismatch in thermal expansion. As a ceramic piece cools from the searing heat of the kiln, both the clay body and the glaze layer contract. When the glaze contracts more than the clay body beneath it, immense tensile stress builds within the glassy surface layer. This tension becomes too great, and the glaze fractures in a seemingly random, yet physically determined, network. These are not cracks through the entire piece, but only within the glaze itself, like the crazing on an old painting.

Experienced potters understand these patterns follow predictable rules. A classic Ge ware crackle typically exhibits two distinct networks: primary cracks measuring 2-3 millimeters apart, with secondary fissures branching between them. The width and character of these cracks depend directly on the degree of thermal expansion mismatch. Research into ceramic materials, such as that published in the Journal of the European Ceramic Society, confirms that a minute difference in the coefficient of thermal expansion between body and glaze is the critical driver. The clay body itself is a key variable; a high-silica porcelain contracts differently than an iron-rich stoneware, demanding specific glaze recipes to achieve the desired effect.

Modern practitioners achieve controlled results through precise material combinations. Pairing a high-silica clay body with a glaze rich in fluxes like sodium or potassium—which typically have higher expansion rates—creates reliable tension. Some workshops add small percentages of materials like magnesium carbonate or talc to their glaze mixture to encourage finer, more intricate crackle networks. The firing and cooling regimen proves equally crucial. The rate of temperature drop through a critical range is a powerful tool. A slow, controlled cooling might yield a large, sparse crackle, while a quicker drop could produce a dense, frenetic network. The kiln atmosphere, whether oxidation or reduction, also subtly influences the final color and texture of the cracks.

Mastering Application and Enhancement Techniques

Applying a crackle glaze is an exercise in precision where consistency and thickness are paramount. Dipping a bisque-fired vessel for a precisely timed six seconds might create an ideal layer—thin enough to crack cleanly without shivering off, yet thick enough to remain durable. Brushing, on the other hand, offers different possibilities. Applying multiple cross-hatched coats can introduce directional tendencies in the crackle pattern, as the brushstrokes create microscopic ridges and valleys. Some potters employ a technique of lightly scoring the glazed surface with a fine needle in a faint grid before firing, creating intentional weak points that guide the crackle along semi-predetermined paths, though this requires a masterful touch to avoid an artificial look.

The true artistic transformation, however, often happens after the fire has done its work. Once cooled, the microscopic cracks become capillary channels for color. This process, known as staining or highlighting, brings the pattern to life. A strong, warm black tea or coffee solution will stain a light-colored crackle within minutes, seeping into the fissures and creating a classic, elegant contrast. For a more permanent and intense effect, pigments like iron oxide or manganese dioxide, suspended in oil or water, are rubbed into the surface and given time—sometimes 48 hours or more—to penetrate fully. The excess is then wiped away, leaving the dark lines embedded in the glaze.

For food-safe pieces, specially formulated ceramic stains or even natural mineral pigments mixed with vinegar offer vibrant, non-toxic alternatives. The absorption rate varies dramatically; wider “canyons” accept pigment readily, while the finest hairline fractures might need repeated applications over several days to become visible. Environmental control post-firing is a secret of many master studios. One renowned Jingdezhen workshop maintains a humidity-controlled room specifically for crackle development. “We keep newly fired pieces at 85% relative humidity for the first week,” explains master potter Li Wei. “The moisture causes the clay body to expand ever so slightly, encouraging the glaze to complete its crackle network uniformly. Without this step, pieces might develop incomplete patterns or suffer from delayed cracking months later when exposed to humidity.”

“Newcomers often ask how to ‘fix’ their crackle when it doesn’t match their vision. I tell them there’s nothing to fix—only adjustments to make next time. The clay remembers every variable: how long you wedged it, how thickly you applied the glaze, even the atmospheric pressure on firing day. Crackle is the clay’s memory made visible.”

— Zhang Mei, third-generation crackle specialist at Hangzhou’s Blue River Studio

Practical Insights for Potters and Enthusiasts

For those seeking to explore Chinese crackle glaze, whether as a practitioner or an admirer, several practical insights can deepen appreciation and guide practice.

Begin with a Proven Foundation: Rather than experimenting blindly, start with a well-documented crackle glaze recipe designed for your specific clay body. Many ceramic resource centers and established artists share reliable base recipes. The key variables to track are the silica-to-flux ratio in the glaze and its fit with your clay’s expansion rate. A small investment in a set of commercial crackle glazes can also provide a reliable baseline for understanding the behavior before formulating your own.

Embrace the Discipline of the Test Tile: Systematic testing is non-negotiable. Fire test tiles at different thicknesses, in different kiln locations, and with varied cooling rates. Keep detailed notes on clay body, glaze thickness, firing schedule, and results. A glaze that crackles beautifully on a small tile might behave differently on a large platter due to thermal mass. Document this process visually; a photo album of test tiles becomes an invaluable personal reference guide.

Staining is an Art Unto Itself: The method of applying stain drastically affects the outcome. Rubbing with a thick paste of pigment and oil gives a bold, graphic line. Washing with a thin, watery stain creates a softer, more subtle, aged effect. Experiment on broken shards or the backs of test tiles first. Remember that oil-based stains penetrate deeper but require thorough cleaning with solvents for functional ware, while water-based stains are simpler but may not seep as deeply into fine cracks.

Consider Functionality and Care: A common concern is whether crackle-glazed pottery is food-safe or durable. A properly formulated and fired crackle glaze is perfectly durable for everyday use. The fine cracks do not go through the pot and do not inherently harbor bacteria if the piece is glazed underneath the crackle layer and fired to maturity. However, for items that will hold acidic liquids like coffee or orange juice, or that require rigorous hygiene, many potters recommend using an intact, non-porous glaze. For decorative pieces, this is a non-issue, but for a daily-use tea bowl, it’s a critical consideration. General guidelines for ceramic food safety often align with principles outlined by health authorities.

Develop a Collector’s Eye: When appreciating or collecting crackle ware, look beyond the pattern itself. How does the crackle interact with the form? On a tea bowl, a finer crackle at the rim where it meets the lips can create a delicate tactile experience, while a large vase might use a graduated pattern to guide the eye along its curves. The finest pieces demonstrate a unity between form, glaze color, and crackle character. Notice the color of the stain—a warm brown suggests tea or iron oxide, while a cooler black may indicate manganese. The depth and clarity of the lines speak to the skill of the staining process.

The Contemporary Resonance of an Ancient Technique

In today’s ceramic art world, Chinese crackle glaze is far from a historical relic. Contemporary artists draw upon its vocabulary to express modern concepts. Some use the crackle as a metaphor for fragility, memory, or the passage of time—the “memory made visible” that Zhang Mei describes. Others employ it in massive, architectural installations, scaling the intimate Song aesthetic to monumental proportions. The technique has also fused with other global ceramic traditions, creating hybrid forms that speak to a connected artistic world. Market analyses from firms like Statista show a growing interest in artisan ceramics and handmade objects, within which pieces utilizing historical techniques like crackle hold a special place for their narrative depth.

The technique’s digital-age relevance is poignant. In a world often seeking sterile perfection, the deliberate, organic imperfection of crackle glaze offers a resonant counterpoint. It is a testament to wabi-sabi long before the term was popularized in the West, embracing transience, asymmetry, and the beauty of the imperfect. It connects the modern maker or admirer to a lineage of artisans who, centuries ago, learned to listen to the whispers of cooling porcelain and see not failure, but profound beauty.

It transforms a simple vessel into a landscape, a map of its own creation, inviting us to look closer and find a universe in a single, deliberate flaw. The next time you hold a piece of crackle ware, run a finger gently over its surface. Feel the texture of history, science, and artistry fused into one. Listen for the echo of that quiet ping from the kiln, a sound that has resonated for a thousand years, a secret still being told.

You may also like

The Palace Museum Paper-Cut Light Art Fridge Magnets: Chinese Cultural Style Creative Gift Series

Price range: $27.00 through $36.00 Select options This product has multiple variants. The options may be chosen on the product pageAncient Craftsmanship & ICH Herbal Beads Bracelet with Yellow Citrine & Silver Filigree Cloud-Patterned Luck-Boosting Beads

Original price was: $128.00.$89.00Current price is: $89.00. Add to cartAncient Craft Herbal Scented Bead Bracelet with Gold Rutile Quartz, Paired with Sterling Silver (925) Hook Earrings

Original price was: $322.00.$198.00Current price is: $198.00. Add to cartGuangxi Zhuang Brocade Handmade Tote – Ethnic Boho Large-Capacity Shoulder Bag

Original price was: $172.00.$150.00Current price is: $150.00. Add to cartBambooSoundBoost Portable Amplifier

Original price was: $96.00.$66.00Current price is: $66.00. Add to cartHandwoven Zhuang Brocade Tote Bag – Large-Capacity Boho Shoulder Bag

Original price was: $178.00.$154.00Current price is: $154.00. Add to cart