The Material Foundation: Nature’s Flexible Strength

Rattan bamboo stands as one of Earth’s most remarkable renewable resources, combining extraordinary tensile strength with almost supernatural flexibility. These climbing palms differ fundamentally from traditional bamboo—while bamboo grows as hollow culms, rattan develops as solid-core vines that can reach astonishing lengths of over 600 feet in tropical forests. This unique growth pattern creates dense fiber bundles that resist snapping under pressure, making rattan three times more flexible than oak while maintaining comparable strength.

The material’s cellular architecture deserves particular attention. Microscopic examination reveals longitudinally aligned fibers surrounded by parenchyma cells that act as natural shock absorbers. This biological design allows rattan to bend to extreme angles without fracturing, then return to its original form. Furniture conservator Michael Torres describes this quality: “I’ve seen century-old rocking chairs that still bear the gentle curve of their original owner’s posture—the material remembers without breaking.”

Freshly harvested rattan contains approximately 40% moisture content, giving it almost clay-like workability for intricate weaving. The curing process transforms this pliable vine into a stable building material through careful drying that reduces moisture to 12-15%. This transformation isn’t merely about water evaporation—the lignin between fibers polymerizes, creating permanent bonds while maintaining flexibility. Unlike synthetic materials that degrade through plastic fatigue, properly cured rattan actually improves with age as the fibers compress and interlock more deeply.

The patina that develops over years of use tells a story of human interaction. Natural oils from hands, subtle scratches from movement, and light exposure create a luminous quality that synthetic materials cannot replicate. As UNESCO notes in their study on traditional crafts, “The aging of natural materials like rattan represents a dialogue between human use and material response—a tangible record of shared history.”

Material Selection and Preparation: The Art of Reading Fibers

Successful rattan work begins long before the first weave—it starts with understanding how to select and prepare materials. For structural elements, choose rattan poles with consistent diameter and minimal visible scarring. The distance between nodes should be regular, indicating steady growth conditions. For weaving work, select strands cut from the outer layers of mature vines, where fiber density is highest.

Bamboo selection requires different criteria. Look for culms harvested during the dry season when sugar content is lowest, reducing susceptibility to insects. The wall thickness should be consistent around the circumference, and the color should be uniform without dark spots or mold signs. Statista reports that proper selection can increase material lifespan by up to 70% compared to randomly chosen specimens.

Preparation methods vary by project type. For furniture frames, soak rattan poles in warm water (approximately 110°F) for 45-90 minutes until pliable. For weaving strands, extend soaking to two hours, but add a tablespoon of salt per gallon to prevent microbial growth. Maria Santos, a third-generation basket weaver from the Philippines, shares her family’s technique: “We soak strands in seawater overnight—the minerals seem to make the rattan more supple. Then we rinse in fresh water before weaving.”

When working with older pieces, resurrection requires different approaches. A mixture of water and glycerin (roughly 10:1 ratio) sprayed every 20 minutes prevents century-old fibers from splitting during repair. For bamboo elements showing signs of dryness, lightly sanding then applying linseed oil restores flexibility and protects against moisture loss.

Structural Weaving Techniques: Where Rhythm Meets Precision

The fundamental under-over pattern forms the backbone of rattan work, but mastery lies in understanding tension. Proper tension feels like a firm handshake—enough pressure to secure the weave without distorting the material’s natural alignment. Work in sections no wider than your palm span, completing each area before moving to the next. This systematic approach prevents uneven tension that can cause warping over time.

Sarah Chen’s rhythmic method demonstrates how experienced weavers internalize measurements. “Three passes, one adjustment. Two weaves, one check,” she explains while creating a room divider containing over 300 feet of rattan. “The counting becomes meditation—your hands learn the spacing without conscious thought.” Her students typically require six months to develop this muscle memory, after which their work shows dramatic improvement in consistency.

The lock-weave method represents one of rattan work’s most valuable techniques for joining elements. By wrapping the working end twice around the structural frame before continuing the pattern, you create friction-based security that actually strengthens as the fibers settle. This method distributes stress across multiple contact points rather than concentrating it at knots or ties.

For complex shapes, the bias weaving technique allows creation of compound curves. By angling strands at 45 degrees to the frame, the material can follow dramatic contours while maintaining structural integrity. Furniture maker James Watanabe describes its application: “When creating the curved back for a chaise lounge, bias weaving lets the rattan flow like fabric over the form while providing firm support.”

Advanced Applications and Modern Innovations

Contemporary designers are pushing rattan bamboo into unexpected territories. Architects now use laminated rattan for structural elements in sustainable buildings, while lighting designers exploit its translucency when sliced thinly to create ethereal illumination effects. The material’s vibration absorption makes it ideal for musical instrument components, and its thermal properties suit it for kitchen implements that remain cool to touch even in warm environments.

In the automotive industry, engineers are experimenting with rattan composites for interior panels and trim pieces. The material’s excellent strength-to-weight ratio—combined with its sustainable credentials—makes it increasingly attractive to manufacturers seeking alternatives to petroleum-based materials. A recent study published in the Journal of Composite Materials demonstrated that rattan-reinforced biocomposites could match the performance of fiberglass in certain applications while being fully biodegradable.

Medical applications are emerging as well. The natural flexibility and shock-absorbing qualities of rattan make it suitable for certain orthopedic devices and rehabilitation equipment. Prosthetists have begun using rattan in temporary limb supports where its gradual “memory” effect can help patients adapt to new movements.

Practical Applications and Maintenance: From Creation to Preservation

Modern rattan applications extend far beyond traditional furniture. The material’s versatility shines in everything from architectural screens that filter light while allowing air circulation to garden structures that weather gracefully without chemical treatments.

Daily maintenance requires minimal effort. Dust with a soft brush following the grain direction, and occasionally wipe with a damp cloth. For deeper cleaning, use mild soap solution followed by thorough drying. Avoid silicone-based polishes that create surface buildup—instead, annually apply a thin coat of tung or linseed oil to maintain flexibility and luster.

Repair techniques vary by damage type. For loose weaving, lightly mist with water and retighten while damp. For broken structural elements, create splints from fresh rattan secured with natural fiber cordage until the repair integrates with the original material. As the World Health Organization notes in their indoor air quality guidelines, “Natural fiber repairs typically off-gas fewer volatile compounds than synthetic adhesives, contributing to healthier indoor environments.”

Climate considerations significantly impact rattan longevity. In arid environments, maintain 40-50% humidity through room humidifiers or occasional misting. In tropical climates, ensure adequate air circulation to prevent mold. The material naturally expands and contracts with seasonal humidity changes—this movement is normal and should be accommodated in design.

Sustainable Harvesting and Future Directions

Rattan’s sustainability story deserves particular attention. As a fast-growing vine that thrives in shaded forest understories, rattan cultivation preserves canopy cover while providing economic opportunities for forest communities. Properly managed rattan stands can be harvested every 7-10 years without ecosystem damage, making it one of the most renewable structural materials available.

The Forest Stewardship Council certification system now includes rattan, ensuring consumers can identify products from responsibly managed sources. Research from the Center for International Forestry Research indicates that “community-based rattan management generates higher long-term income than conversion to agriculture while maintaining biodiversity.”

Innovation continues to expand rattan’s possibilities. Scientists have developed techniques for bending thicker poles using steam boxes that soften lignin without damaging fibers. Designers experiment with rattan composites mixed with bio-resins for outdoor applications. The material’s excellent strength-to-weight ratio makes it increasingly interesting to transportation industries seeking sustainable alternatives to synthetic materials.

The future of rattan lies in honoring traditional knowledge while embracing technological advances. As master weaver Elena Rodriguez observes, “My grandmother knew twenty different weaving patterns from memory. Today, we have those patterns plus computer modeling to test new designs. The old wisdom and new tools together create possibilities our ancestors never imagined.” This balance between tradition and innovation ensures rattan’s place in both our heritage and our future, bridging centuries of craftsmanship with contemporary design needs while supporting forest conservation and community livelihoods across the tropical regions where it grows.

You may also like

Guangxi Zhuang Brocade Handmade Tote – Ethnic Boho Large-Capacity Shoulder Bag

Original price was: $172.00.$150.00Current price is: $150.00. Add to cartHandwoven Zhuang Brocade Tote Bag – Large-Capacity Boho Shoulder Bag

Original price was: $178.00.$154.00Current price is: $154.00. Add to cartAladdin’s Lamp Heat-Change Purple Clay Tea Pot

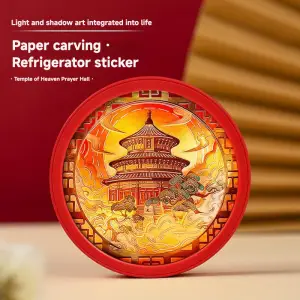

Original price was: $108.00.$78.00Current price is: $78.00. Add to cartThe Palace Museum Paper-Cut Light Art Fridge Magnets: Chinese Cultural Style Creative Gift Series

Price range: $27.00 through $36.00 Select options This product has multiple variants. The options may be chosen on the product pageBambooSoundBoost Portable Amplifier

Original price was: $96.00.$66.00Current price is: $66.00. Add to cartAncient Craft Herbal Scented Bead Bracelet with Gold Rutile Quartz, Paired with Sterling Silver (925) Hook Earrings

Original price was: $322.00.$198.00Current price is: $198.00. Add to cart