Good leatherwork begins with the understanding that materials teach more than instructions ever could. A vegetable-tanned shoulder tells stories through its temper and pull-up; a well-worn skiver reveals its purpose through repeated use. This isn’t about artistic odysseys or market trends—it’s about developing reliable hands that can translate intention into durable objects. The journey from novice to confident maker is paved with practical knowledge, a deep respect for the material, and the quiet repetition that builds skill. While countless leathercraft tutorials exist online, the true education happens in the dialogue between your hands, your tools, and the leather itself.

The Foundation: Reading Grain and Guiding Blades

Before making the first cut, successful makers learn to read leather like a map. Run your thumb across the surface—the tight, smooth area near the backbone offers different resistance than the looser flank. This matters because grain direction determines how edges behave when folded, how stitches settle, and how the piece ages. A simple card holder cut against the grain might cup unpredictably after six months of pocket wear. This fundamental step is often glossed over in beginner tutorials, yet it is the cornerstone of predictable results. Leather is a natural, anisotropic material, meaning its properties change with direction, much like wood. Understanding this is your first step toward working with the material, not against it.

Cutting techniques follow this material awareness. Many beginners press too hard, fighting the leather rather than guiding the blade. Try this instead: position your pattern, take a breath, and draw the knife with consistent, moderate pressure. Let the sharpness do the work. A sharp blade is safer and more accurate than a dull one requiring force. After cutting fifty identical belt loops, your hand will remember the angle that produces clean edges without slicing into the cutting mat beneath. This repetition builds what old saddlemakers called ‘hand wisdom’—the unconscious adjustments that separate deliberate work from hesitant attempts.

Start with a sharp utility knife or a dedicated round knife, and always use a self-healing cutting mat and a metal ruler for straight lines. Your initial projects may be simple rectangles and straps; this is not a waste of material but an investment in muscle memory. Sarah, who began her leatherwork journey during the pandemic, shares: “I spent my first week just cutting straight lines and smooth curves from an old belt. It felt silly until I moved to my first wallet kit. My cuts were clean, and I wasn’t terrified of the knife anymore. That foundational practice saved me so much frustration and leather.”

Stitching That Endures: Consistency Over Speed

Hand stitching often intimidates newcomers, but its principles are mechanical rather than mystical. The goal isn’t perfect symmetry but consistent tension. Each stitch should bear equal load; a single loose loop weakens the entire seam. Start by practicing on scrap leather with two needles and waxed thread. Pierce at a consistent 45-degree angle, pull until the thread just beds into the leather—not so tight it distorts the material, not so loose it loops. The choice of thread and needle size should correspond to your leather’s thickness; a thread that is too thick for fine leather will look bulky and strain the holes.

Watch an experienced maker at work. Their rhythm looks leisurely—punch, pass, pull, pause—but produces eight stitches per inch that look identical. They’re not counting; they’re feeling the thread’s resistance through their fingers. ‘I ruined three bags before realizing my problem wasn’t technique but patience,’ admits workshop instructor Mara Chen. ‘Rushing the pull created uneven tension that looked fine initially but caused seams to fail within a year.’ Her solution? Practice stitching two-inch seams daily for a month, focusing solely on maintaining identical pull pressure. The muscle memory developed transfers to every subsequent project. This disciplined approach transforms stitching from a chore into a meditative, reliable process.

This approach extends to tool maintenance. A dull stitching awl or diamond chisel requires more force, disrupting rhythm and consistency. Sharpening becomes part of the workflow, not an occasional chore. A well-maintained tool not only produces better results but also makes the craft more enjoyable and less physically taxing.

‘When an apprentice asks about creativity, I show them my first fifty key fobs,’ says professional leatherworker David Reyes. ‘The first ten are embarrassing—uneven edges, wandering stitches. By number thirty, the hands start working without constant supervision from the brain. By fifty, they’re practically identical. That repetition isn’t monotonous; it’s freedom. Once your hands know how to execute fundamentals reliably, you can actually focus on design rather than struggling with execution.’

Selecting and Understanding Your Materials

The quality of your materials profoundly impacts both your process and the final product. Vegetable-tanned leather, for instance, is a favorite for tooling and molding because it retains impressions and patinas beautifully over time. Chrome-tanned leather offers greater water resistance and a softer hand, making it ideal for bags and apparel. According to industry analyses from Statista, the global leather goods market continues to value both mass-produced and artisanal items, with a growing consumer interest in sustainability and traceability. Knowing your leather’s origin and tannage helps you choose the right material for the job and understand its behavior.

Start with a medium-weight (3-4 oz) vegetable-tanned side for practice. It is forgiving, readily available, and excellent for developing fundamental skills. As you progress, you’ll learn to feel the differences in temper, thickness, and finish. Remember, the best leathercraft tutorials can guide you, but only hands-on experience will teach you how a particular leather cuts, bends, and burnishes. Don’t be afraid to ask suppliers for small samples; feeling the difference between a full-grain hide and a corrected grain is an essential tactile lesson.

From Tutorials to Mastery: Building a Personal Practice

Leathercraft tutorials are invaluable starting points, but they are maps, not the territory. The real learning is tactile and iterative. A study on skill acquisition in manual trades, published in the Journal of Vocational Education & Training, emphasizes the role of deliberate practice—focused, repetitive effort with immediate feedback—over passive learning. Each time you bevel an edge, dye a panel, or set a snap, you are gathering this feedback. A wallet becomes a record of improved edge finishing; a tool roll documents better spacing between rivets. The craft progresses not through theoretical leaps but through accumulated, tangible experience at the workbench.

Create a dedicated practice regimen. Allocate time not just for projects, but for skill drills. Cut curves and circles from scrap. Practice punching a perfectly straight line of stitching holes. Experiment with different edge finishing techniques on leather off-cuts. This focused practice removes the pressure of a “perfect” final product and accelerates your learning curve faster than completing projects alone ever could. Set up a simple reference board: glue small squares of different leathers, threads, and finished edges to a piece of wood. This becomes a quick, physical guide far more useful than any digital folder.

Finishing Well: The Details That Define Quality

A project isn’t finished when the last stitch is tied. The final 10% of the work—edge finishing, polishing, and conditioning—often determines 90% of the perceived quality. Sand your edges progressively with finer grits of sandpaper, from 400 up to 1000 or higher. Apply a burnishing gum or water and use a wood slicker, canvas cloth, or even the edge of a wooden desk to generate friction and heat. This melts the leather fibers together, creating a smooth, sealed edge that feels as good as it looks.

Protect and nourish the leather with a suitable conditioner. Products like neatsfoot oil, mink oil, or specialized leather balms will prevent drying and cracking, especially in arid climates. The World Health Organization notes that proper maintenance of materials, even in non-medical contexts, extends their functional lifespan and sustainability—a principle that applies perfectly to leather goods. A well-maintained item can last for decades, becoming a personal heirloom. Tom, a retired engineer, still carries the belt his father made in the 1950s. “He conditioned it with beeswax once a year,” Tom recalls. “The leather is soft, dark, and covered in tiny scars from his workshop. It’s outlasted every store-bought belt I’ve ever owned.”

The Toolbox: Building Your Kit Intentionally

Faced with endless online catalogs, beginners often ask, “What tools do I really need?” The answer is simpler than most leathercraft tutorials suggest. Start with the essentials for your chosen path. For basic stitching and assembly, a core kit includes: a cutting mat, utility knife, metal ruler, diamond-point stitching chisels, a stitching pony, needles, waxed thread, a wooden edge beveler, a mallet, and sandpaper. Resist the urge to buy every specialized tool immediately. Learn the limits of your basic tools first; this knowledge will inform your future purchases.

Quality over quantity is paramount. A single, well-made #2 edge beveler from a reputable brand will serve you better than a cheap set of ten. As your skills grow, you’ll add tools intentionally—a pricking iron for finer holes, a skiver for thinning leather, specific stamping tools for decoration. Your toolkit should evolve with your practice, not precede it. Many seasoned makers have a “first toolbox” tucked away, a humble collection that built their foundational competence.

Cultivating a Sustainable and Mindful Craft

Leathercraft, at its best, is an antidote to disposable culture. It encourages resourcefulness, patience, and a deep connection to the objects we use daily. UNESCO recognizes similar values in its lists of intangible cultural heritage, which include traditional craftsmanship systems worldwide, noting their role in fostering sustainability and community. As a leatherworker, you participate in this tradition. Use every scrap of leather—small pieces become key fobs, test patches, or filler material. Properly maintain your tools so they last a lifetime. Share your knowledge with others, as the community of makers is one of the craft’s greatest resources.

Embrace the mistakes. A misplaced stamp or an uneven cut is not a failure but a lesson embedded in the material. These “flaws” often become the unique character of a piece, reminders of the human hands that made it. The goal is not machine-like perfection, but the creation of functional, beautiful objects imbued with care and skill. This mindful approach transforms the workshop from a mere production space into a studio for focused, sustainable creation.

These foundations—reading material, controlled cutting, consistent stitching, mindful finishing—create a virtuous cycle. Each completed project, however simple, reinforces physical understanding. Your hands become more confident, your eyes more discerning. You begin to anticipate how leather will react before you make a mark. This is the true outcome of dedicated practice: a quiet competence that allows creativity to flourish, ensuring that every item you create is not just made, but crafted to endure.

You may also like

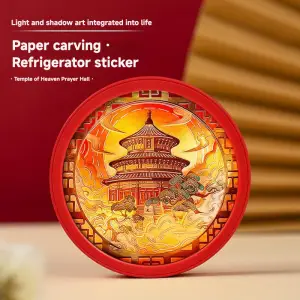

The Palace Museum Paper-Cut Light Art Fridge Magnets: Chinese Cultural Style Creative Gift Series

Price range: $27.00 through $36.00 Select options This product has multiple variants. The options may be chosen on the product pageAncient Craft Herbal Scented Bead Bracelet with Gold Rutile Quartz, Paired with Sterling Silver (925) Hook Earrings

Original price was: $322.00.$198.00Current price is: $198.00. Add to cartAncient Craftsmanship & ICH Herbal Beads Bracelet with Yellow Citrine & Silver Filigree Cloud-Patterned Luck-Boosting Beads

Original price was: $128.00.$89.00Current price is: $89.00. Add to cartAladdin’s Lamp Heat-Change Purple Clay Tea Pot

Original price was: $108.00.$78.00Current price is: $78.00. Add to cartGuangxi Zhuang Brocade Handmade Tote – Ethnic Boho Large-Capacity Shoulder Bag

Original price was: $172.00.$150.00Current price is: $150.00. Add to cartHandwoven Zhuang Brocade Tote Bag – Large-Capacity Boho Shoulder Bag

Original price was: $178.00.$154.00Current price is: $154.00. Add to cart