Walk through any bamboo forest and you’ll hear more than rustling leaves—you’re listening to one of nature’s most efficient carbon capture systems at work. While bamboo has been part of human civilization for millennia, recent technological advances are unlocking its potential in ways that defy traditional expectations of this humble grass. The gentle creaking of bamboo stalks in the wind belies a material revolution quietly unfolding across industries worldwide, from construction sites in Colombia to textile factories in Vietnam.

The Material Science Breakthrough

What makes bamboo particularly compelling today isn’t just its sustainability credentials but its remarkable mechanical properties. With a tensile strength that rivals steel and a growth rate that outpaces most timber by twenty times, bamboo represents a paradox of strength and speed. Researchers at the Singapore University of Technology have developed cross-laminated bamboo panels that maintain structural integrity under loads exceeding 500 kilograms per square meter. “We’re not just working with bamboo—we’re engineering with it,” notes Dr. Elena Rodriguez, whose team has pioneered new lamination techniques that allow bamboo to compete directly with traditional construction materials in applications ranging from flooring to full structural systems.

The Bamboo Engineering Research Center at Southeast University in China has demonstrated that properly processed bamboo can achieve compressive strengths comparable to concrete while weighing significantly less. This combination of lightness and durability makes it particularly valuable in earthquake-prone regions, where traditional heavy building materials can become deadly during seismic events. In Costa Rica, architects have completed a three-story bamboo structure that survived a 6.4 magnitude earthquake with minimal damage, while neighboring concrete buildings suffered significant cracking.

Modern processing techniques have overcome bamboo’s historical limitations with consistency and susceptibility to insects and moisture. Advanced treatment methods including thermal modification and resin impregnation create dimensionally stable bamboo products that resist decay while maintaining the material’s natural aesthetic. The World Health Organization has noted the health benefits of bamboo building materials in tropical climates, where their natural breathability reduces mold growth and improves indoor air quality.

Beyond Construction: Diversification Across Industries

The bamboo industry is rapidly expanding beyond its traditional domains into textiles, automotive manufacturing, and technology. In Vietnam, factories now produce bamboo-based textiles that feel indistinguishable from high-quality cotton but require 80% less water to manufacture. The process transforms bamboo pulp into soft, breathable fabric through closed-loop systems that recycle processing chemicals, minimizing environmental impact. A single bamboo plant can yield enough fiber for approximately twenty t-shirts while continuously regenerating from the same root system.

European automotive companies are experimenting with bamboo composites for interior panels, drawn to both the material’s lightweight properties and its carbon-negative lifecycle. BMW’s i3 electric vehicle incorporated bamboo fibers in its interior components, reducing weight while creating a warm, natural aesthetic. The choice wasn’t merely stylistic—every kilogram reduced in vehicle weight translates to extended battery range and lower emissions over the vehicle’s lifetime.

Perhaps most surprisingly, bamboo has entered the technology sector through bamboo charcoal coatings for electronic devices, which provide both antimicrobial protection and electromagnetic shielding. Japanese electronics company Murata Manufacturing has developed bamboo charcoal-based materials that absorb electromagnetic interference in sensitive medical and communication equipment. Meanwhile, smartphone cases treated with bamboo charcoal demonstrate 99% reduction in bacterial growth compared to conventional plastics, according to testing published in the Journal of Materials Science.

“When we started using bamboo composites in our furniture line three years ago, customers were skeptical. Now it’s our fastest-growing category, with orders increasing 40% annually. The material’s story—rapidly renewable, carbon-sequestering, incredibly durable—resonates with both designers and environmentally conscious consumers.” — Maria Chen, Product Director at TerraForm Living

Environmental Impact and Carbon Sequestration

Bamboo’s environmental credentials extend far beyond its rapid growth cycle. A mature bamboo grove can sequester up to 400% more carbon than a similar stand of hardwood trees, according to research from UNESCO’s Forest Ecology Program. Unlike trees that must be replanted after harvesting, bamboo regenerates from its extensive root system, maintaining soil integrity and preventing erosion. This continuous harvesting actually stimulates further growth while keeping carbon locked in the root mass.

In Ethiopia’s highlands, communities have planted bamboo along riverbanks to stabilize soil and filter agricultural runoff. The initiative has not only improved water quality but created new economic opportunities through sustainable harvesting. “Before bamboo, the riverbanks would collapse during heavy rains, taking valuable topsoil with them,” explains local farmer Abebe Teshome. “Now the bamboo holds everything in place, and we harvest poles for construction while the plants keep growing.”

The plant’s water efficiency makes it particularly valuable in regions facing climate-induced drought. Bamboo’s deep root system and waxy leaf coating reduce water loss, allowing it to thrive where other crops fail. In India’s drought-prone Maharashtra state, farmers have intercropped bamboo with traditional crops, creating microclimates that reduce soil temperature and evaporation rates while providing additional income from bamboo harvests.

Practical Applications and Daily Use

For homeowners considering bamboo products, several factors determine quality and longevity. In flooring, look for strand-woven bamboo with low VOC (volatile organic compound) adhesives. This manufacturing process compresses bamboo fibers under extreme pressure, creating a product harder than most hardwoods. Proper acclimation before installation is crucial—allow planks to sit in the room where they’ll be installed for at least 72 hours to adjust to local humidity levels.

Bamboo textiles offer exceptional comfort but require specific care. Wash bamboo clothing in cold water with mild detergent and avoid fabric softeners, which can clog the fibers’ natural breathability. The material’s natural moisture-wicking properties make it ideal for athletic wear and bedding, though consumers should verify that manufacturers use closed-loop processing systems to ensure environmental benefits aren’t undermined by chemical pollution.

For DIY enthusiasts, bamboo makes excellent garden structures and fencing. The material naturally resists weathering and develops an attractive silver patina when left untreated. When building with bamboo poles, select mature stalks (at least three years old) with closely spaced nodes, as these indicate higher density and strength. Traditional joinery techniques using lashing rather than nails better accommodate bamboo’s natural movement and prevent splitting.

Economic Opportunities and Community Impact

The bamboo sector has created sustainable livelihoods in rural communities worldwide. In Ghana, the Bamboo and Rattan Development Programme has trained over 2,000 farmers in sustainable cultivation and processing techniques. Many participants have doubled their household incomes while restoring degraded lands. “We used to clear forest for farmland, but now we grow bamboo on marginal lands that weren’t good for crops anyway,” explains program participant Ama Serwah. “The bamboo protects the soil and gives us building materials to improve our homes.”

Small-scale enterprises have found niche markets for bamboo products. In Brazil, company BambuBr creates custom bicycles with bamboo frames that absorb road vibration better than carbon fiber. Each frame is unique, handcrafted to the rider’s specifications while supporting local artisans. Founder Carlos Belmonte notes, “Customers appreciate that their bicycle literally grew from the earth rather than being manufactured in a polluting factory. The connection to natural materials enhances the riding experience.”

The economic model works across scales—from individual artisans crafting household items to industrial facilities producing engineered bamboo products. This scalability makes bamboo particularly valuable in developing economies where it can provide both immediate subsistence resources and long-term industrial development opportunities. According to Statista, the global bamboo market is projected to reach $98 billion by 2027, creating millions of jobs in cultivation, processing, and manufacturing.

Future Directions and Innovation

Research continues to expand bamboo’s potential applications across multiple sectors. Scientists at MIT have developed transparent bamboo composites that could replace glass in certain applications while providing better insulation properties. Other teams are exploring bamboo-based biofuels that don’t compete with food crops, and bamboo-derived activated carbon for water filtration systems that could provide affordable clean water solutions in developing regions.

The material’s rapid growth cycle makes it an ideal candidate for carbon credit programs. Companies including Microsoft and Shopify have invested in bamboo afforestation projects to offset their carbon emissions while supporting biodiversity. Unlike monoculture tree plantations, well-managed bamboo forests support diverse undergrowth and wildlife while generating harvestable products annually rather than waiting decades between harvests.

As climate change intensifies, bamboo’s drought resistance and carbon sequestration capabilities position it as a crucial tool in climate mitigation strategies. Its ability to regenerate without replanting and thrive on marginal lands makes it particularly valuable for restoring degraded ecosystems while providing economic benefits to local communities. From its role in climate change mitigation to its potential in advanced manufacturing, this ancient grass is proving remarkably suited to modern challenges—its gentle rustle in the forest whispering of sustainable solutions growing steadily toward the light.

You may also like

Ancient Craft Herbal Scented Bead Bracelet with Gold Rutile Quartz, Paired with Sterling Silver (925) Hook Earrings

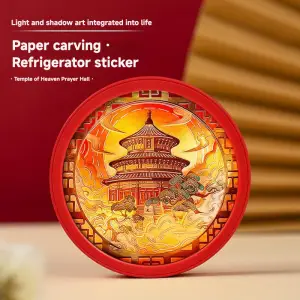

Original price was: $322.00.$198.00Current price is: $198.00. Add to cartThe Palace Museum Paper-Cut Light Art Fridge Magnets: Chinese Cultural Style Creative Gift Series

Price range: $27.00 through $36.00 Select options This product has multiple variants. The options may be chosen on the product pageHandwoven Zhuang Brocade Tote Bag – Large-Capacity Boho Shoulder Bag

Original price was: $178.00.$154.00Current price is: $154.00. Add to cartAladdin’s Lamp Heat-Change Purple Clay Tea Pot

Original price was: $108.00.$78.00Current price is: $78.00. Add to cartBambooSoundBoost Portable Amplifier

Original price was: $96.00.$66.00Current price is: $66.00. Add to cartAncient Craftsmanship & ICH Herbal Beads Bracelet with Yellow Citrine & Silver Filigree Cloud-Patterned Luck-Boosting Beads

Original price was: $128.00.$89.00Current price is: $89.00. Add to cart