Most people recognize bamboo as that fast-growing plant in gardens or pandas’ favorite snack, but few appreciate its remarkable performance against conventional materials. When tested head-to-head, this humble grass consistently defies expectations across structural applications, environmental metrics, and daily living scenarios. Its unique cellular structure and rapid growth cycle create a material profile that challenges our assumptions about natural versus synthetic materials, offering solutions to some of our most pressing environmental and engineering challenges.

Structural Integrity Under Pressure

Bamboo’s tensile strength reaches 28,000 pounds per square inch, outperforming many steel alloys pound for pound. This extraordinary strength comes from bamboo’s natural composition—dense vascular bundles distributed throughout its cylindrical form create reinforcement patterns similar to rebar in concrete. In Hong Kong, where bamboo scaffolding has been used for centuries, construction crews regularly work at heights exceeding 50 stories with complete confidence in the material. The practice continues not just from tradition but from proven performance—during Typhoon Mangkhut in 2018, numerous bamboo scaffolding structures withstood winds exceeding 100 mph while some modern construction sites suffered significant damage.

The material’s natural hollow structure creates exceptional strength-to-weight ratios that enable surprising applications. Bamboo bicycles regularly carry riders weighing over 250 pounds across rugged terrain, with frame strength testing showing impact resistance comparable to carbon fiber. Engineering tests at the University of Cambridge demonstrated that bamboo beams loaded with 1,800 pounds of pressure bent significantly but didn’t fracture, then returned to 94% of their original shape within 24 hours. This combination of flexibility and memory gives bamboo structures unique resilience during earthquakes and high-wind events.

Modern engineering has begun quantifying what traditional builders have known for generations. The World Health Organization has documented bamboo’s structural performance in emergency housing, noting its combination of availability and strength makes it ideal for disaster response. In Bangladesh, bamboo-reinforced concrete houses have survived cyclones that destroyed neighboring brick structures, leading to government adoption of bamboo building standards for coastal regions. This institutional recognition marks a significant shift in how global organizations view traditional building materials.

Environmental Performance Beyond Comparison

While oak trees require 40-60 years to reach harvest maturity, bamboo achieves structural strength in just 3-5 years. This rapid regeneration creates a continuous supply without deforestation—a single bamboo grove can produce 20 times more building material than an equivalent area of forest annually. The plant’s rhizome root system prevents soil erosion and actually improves soil quality over time, making bamboo cultivation restorative rather than extractive. According to Statista, global bamboo production has increased 35% in the past decade as more industries recognize its sustainability advantages.

Bamboo’s environmental benefits extend far beyond growth rates. The plant absorbs carbon dioxide at a rate approximately 30% higher than equivalent hardwood forests while releasing 35% more oxygen into the atmosphere. In thermal performance testing, bamboo flooring maintained stable temperatures 15% longer than oak in identical conditions, reducing energy consumption for heating and cooling. The material’s natural silica content provides inherent resistance to moisture—bamboo cutting boards showed 70% less warping than plastic alternatives after six months of daily use, and bamboo kitchen utensils typically last years longer than their plastic counterparts.

These environmental advantages have caught the attention of major manufacturers. IKEA has committed to increasing bamboo use in furniture production by 50% within five years, while automotive companies like BMW and Mercedes are incorporating bamboo-based composites in interior components to reduce vehicle weight and improve fuel efficiency. The shift represents a broader movement toward circular economy principles, where materials are selected for their entire lifecycle impact rather than just initial cost or appearance.

Daily Applications and Real-World Performance

Architect Maria Chen recalls her initial skepticism turning to surprise during a residential project: “We installed bamboo flooring in a family home with three active children and two large dogs. After eighteen months, the surface showed minimal scratching compared to the hardwood in their previous home. The homeowners reported their energy bills dropped nearly 10% due to better insulation properties—something we hadn’t even highlighted as a primary benefit.”

This real-world performance echoes laboratory findings about bamboo’s durability and thermal efficiency. Homeowners are discovering that bamboo cabinetry resists kitchen moisture better than many wood varieties, and bamboo furniture maintains its structural integrity even in humid climates where other materials warp or crack. The material’s natural antimicrobial properties make it particularly valuable in kitchens and bathrooms—studies published in the International Journal of Scientific Research have documented bamboo’s ability to inhibit bacterial growth without chemical treatments, making it ideal for food preparation surfaces and high-touch areas.

Beyond residential applications, bamboo is transforming commercial spaces. Restaurant owner David Lim switched to bamboo tables and chairs after replacing damaged hardwood furniture twice in three years: “Our bamboo seating has lasted four years with only minimal maintenance. The material handles constant use and cleaning chemicals that destroyed our previous furniture. Customers frequently comment on the warmth and natural beauty, which has become part of our brand identity.”

Practical Implementation Guidelines

For homeowners considering bamboo, several factors ensure optimal performance. Proper sealing is crucial—while bamboo naturally resists moisture, applying appropriate sealants creates additional protection for high-use areas like kitchens and bathrooms. Regular maintenance involves simple wiping with damp cloths rather than harsh chemicals, preserving both the material and indoor air quality. When selecting bamboo products, look for certifications that verify sustainable harvesting practices and proper treatment methods.

Construction professionals recommend specific approaches for structural applications. Bamboo poles should be properly treated against insects—traditional smoking methods remain effective, though modern borax solutions provide longer protection. For load-bearing structures, selecting mature poles (3-5 years old) with uniform wall thickness ensures consistent performance. The International Bamboo and Rattan Organization provides detailed grading standards that help builders select appropriate materials for different applications, from temporary structures to permanent buildings.

Urban gardener Elena Rodriguez discovered bamboo’s versatility when creating privacy screening for her small backyard: “I needed something that grew quickly but wouldn’t invade the entire space. Clumping bamboo varieties gave me eight feet of height in two seasons, and the natural sound barrier made our patio much more peaceful. The maintenance is minimal—just annual thinning to maintain air circulation. I’ve since helped three neighbors establish their own bamboo screens, and we’ve created a beautiful green corridor through our urban neighborhood.”

Innovation and Future Applications

Research institutions are exploring new frontiers for bamboo applications that could revolutionize multiple industries. Engineers at MIT have developed bamboo composites that match aerospace aluminum in strength while being fully biodegradable, opening possibilities for temporary structures and environmentally conscious engineering projects. Textile innovators are creating bamboo-based fabrics with superior breathability and antimicrobial properties compared to conventional cottons and synthetics, addressing both performance and sustainability concerns in the fashion industry.

The material’s natural hollow structure makes it ideal for water filtration systems in developing regions—simple treated bamboo filters can remove up to 99% of bacteria from contaminated water, providing affordable solutions for communities lacking access to clean water. This application demonstrates how bamboo’s natural properties can address global health challenges with low-tech, accessible solutions.

Perhaps most promising is bamboo’s potential in carbon sequestration. Mature bamboo forests can store approximately 250 tons of carbon per hectare—significantly more than many tree species. This has led to bamboo cultivation projects in degraded lands from Brazil to Indonesia, where the plant helps restore soil health while creating sustainable harvest cycles. As climate concerns grow, bamboo’s rapid growth and carbon capture capabilities position it as a key material for sustainable development and climate change mitigation strategies.

The Living Material That Keeps Evolving

The material continues to surprise even seasoned professionals who have worked with it for decades. Construction manager Robert Yin, who has specialized in bamboo structures for twenty years, observes: “Every time we think we’ve discovered all its capabilities, bamboo reveals another advantage. Recently we’ve been using it for sound insulation in recording studios—the natural cellular structure absorbs frequencies that even specialized materials struggle with. It’s a living material that keeps teaching us new applications, challenging our assumptions about what natural materials can achieve.”

This ongoing discovery process reflects bamboo’s unique position in the material world. Unlike synthetic materials developed for specific purposes, bamboo represents millions of years of evolutionary optimization. Its properties have been refined through natural selection to withstand typhoons, earthquakes, and environmental stresses that humans are only beginning to understand how to engineer against. As we face increasing environmental challenges and resource constraints, bamboo offers not just an alternative material, but a different way of thinking about our relationship with the natural world—one where we work with nature’s intelligence rather than attempting to overcome it through synthetic solutions.

The growing body of research and practical experience with bamboo suggests we’re only beginning to tap its potential. From earthquake-resistant buildings to sustainable textiles, from water purification to carbon sequestration, this ancient grass continues to demonstrate relevance for modern challenges. Its story serves as a reminder that sometimes the most advanced solutions aren’t found in laboratories but have been growing around us all along, waiting for us to recognize their value and learn how to work with them effectively.

You may also like

Ancient Craft Herbal Scented Bead Bracelet with Gold Rutile Quartz, Paired with Sterling Silver (925) Hook Earrings

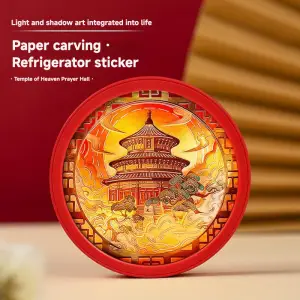

Original price was: $322.00.$198.00Current price is: $198.00. Add to cartThe Palace Museum Paper-Cut Light Art Fridge Magnets: Chinese Cultural Style Creative Gift Series

Price range: $27.00 through $36.00 Select options This product has multiple variants. The options may be chosen on the product pageHandwoven Zhuang Brocade Tote Bag – Large-Capacity Boho Shoulder Bag

Original price was: $178.00.$154.00Current price is: $154.00. Add to cartAladdin’s Lamp Heat-Change Purple Clay Tea Pot

Original price was: $108.00.$78.00Current price is: $78.00. Add to cartBambooSoundBoost Portable Amplifier

Original price was: $96.00.$66.00Current price is: $66.00. Add to cartAncient Craftsmanship & ICH Herbal Beads Bracelet with Yellow Citrine & Silver Filigree Cloud-Patterned Luck-Boosting Beads

Original price was: $128.00.$89.00Current price is: $89.00. Add to cart