In the humid forests of Southeast Asia, where bamboo reaches skyward and rattan vines twist through the undergrowth, human hands have been shaping these materials for over seven thousand years. Archaeological evidence from Borneo reveals rattan baskets dating to 5000 BCE, their intricate patterns speaking across millennia. These weren’t mere containers—they were the first chapters in a story of cultural exchange that would span continents.

The River Routes of Trade

Long before European ships charted these waters, Malay traders carried rattan and bamboo crafts along monsoon routes. A single trading vessel from 14th-century Java might carry three hundred rattan mats, each woven with distinct regional patterns that served as cultural signatures. When Marco Polo described seeing “chairs of woven reeds” in Chinese courts in 1292, he was witnessing the culmination of centuries of Asian craftsmanship. The materials traveled with merchants along the Silk Road’s southern branches, their flexibility making them ideal cargo—lightweight, durable, and packed with potential.

The monsoon winds dictated the rhythm of this trade, with merchants timing their voyages to catch seasonal winds that would carry them from Indonesian archipelago ports to markets in India and East Africa. These routes became conduits not just for goods but for techniques and designs. A rattan weaving pattern developed in Sumatra might appear months later in coastal Sri Lanka, adapted to local materials and aesthetic preferences. The very structure of trade vessels reflected the materials they carried—bamboo outriggers provided stability while rattan lashings held hull planks together, creating ships that were essentially floating demonstrations of their cargo’s versatility.

Colonial Encounters and Cultural Exchange

European colonization created unexpected dialogues between craft traditions. Portuguese settlers in 16th-century Brazil adopted indigenous Tupi-Guarani rattan weaving techniques, blending them with European furniture forms to create what became known as “estilo brasileiro.” This hybrid style featured the curved lines and organic forms of indigenous craftsmanship combined with the structured proportions of European furniture design.

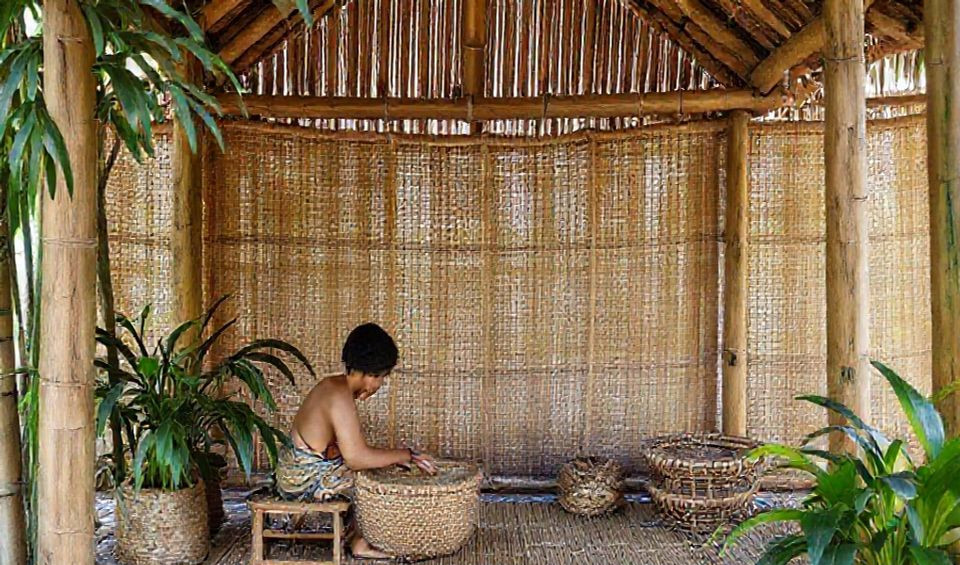

Meanwhile, in the Philippines, Spanish missionaries documented over forty distinct rattan weaving patterns among different ethnic groups, noting how each community used specific bamboo jointing methods passed down through generations. One Spanish chronicler wrote in 1582: “The natives make from these forest vines what our finest carpenters achieve with oak—yet their work bends where ours would break.” This observation highlights the fundamental difference in material philosophy—where European woodworking relied on rigid structures, Southeast Asian craftsmen worked with materials that maintained flexibility and resilience.

“My great-grandmother taught me that rattan remembers the forest long after it’s been cut. When you weave, you’re not just making a basket—you’re continuing a conversation that began when the vine first wrapped around a tree.” — Elena Santos, fourth-generation weaver from Palawan

This living memory of materials persists in workshops from Vietnam’s Mekong Delta to Caribbean islands, where artisans still select bamboo based on lunar cycles and harvest rattan using techniques unchanged for centuries. The continuity isn’t about resisting modernity but understanding that some relationships with nature remain fundamentally timeless.

The Science Behind the Materials

What makes rattan bamboo so remarkably durable yet flexible? The answer lies in their cellular structure. Bamboo’s hollow, segmented stems contain silica deposits that give it tremendous tensile strength—comparable to steel in some applications—while remaining incredibly lightweight. Rattan vines, actually a type of climbing palm, develop long, solid stems that can be peeled into strips without losing structural integrity.

According to research published in the Journal of Materials Science, bamboo’s vascular bundles distributed throughout its structure create a natural composite material that resists cracking and splitting. This explains why bamboo structures have survived earthquakes that toppled concrete buildings, and why rattan furniture can last generations with proper care. The World Health Organization has noted bamboo’s potential as a sustainable building material in developing regions, particularly where traditional materials contribute to deforestation.

Modern Applications and Sustainable Practices

Contemporary designers are rediscovering these ancient materials through the lens of sustainability and biophilic design. Architects like Vo Trong Nghia in Vietnam have created entire bamboo structures that breathe with their environment, their flexibility allowing them to sway gently in wind rather than resisting it. Furniture companies now use rattan in ergonomic office chairs that adapt to the user’s movement, proving that traditional materials can meet modern needs.

The sustainability credentials are impressive. Bamboo reaches maturity in 3-5 years compared to 20-50 years for most timber species, and regenerates from its root system without replanting. A Statista analysis shows the global bamboo product market growing at 5.3% annually, driven by eco-conscious consumers. Rattan cultivation maintains forest canopy cover while providing income for rural communities, creating economic incentives for conservation.

In Costa Rica, the Asoproa cooperative has developed a rattan harvesting method that never takes more than one mature vine per cluster, ensuring continuous regeneration. “We mark each vine we harvest and don’t return to that area for seven years,” explains cooperative leader Maria Gutierrez. “The forest has its own accounting system—we just need to learn how to read it.”

Practical Tips for Working with Rattan Bamboo

For those interested in experimenting with these materials, several considerations can improve results. Always source from certified sustainable suppliers—look for FSC certification or equivalent local standards. When working with bamboo, harvest during the dry season when sugar content is lowest, reducing susceptibility to insects.

For rattan furniture care, occasional misting with water maintains flexibility in dry climates. Avoid direct sunlight which can cause premature brittleness. Minor scratches can often be remedied by lightly steaming the area and applying a small amount of linseed oil. As Indonesian craftsman Wayan Surya notes, “Rattan tells you when you’re working against its nature. Listen to the sound it makes when you bend it—a gentle creak means yes, a sharp crack means stop.”

Modern joinery techniques have expanded possibilities while respecting material properties. Combining rattan with recycled metals or reclaimed wood creates pieces that bridge traditional craftsmanship and contemporary design. The key is understanding that these are living materials even after harvesting—they respond to humidity, temperature, and how they’re handled.

Cultural Preservation Through Craft

Beyond their physical properties, rattan bamboo carry cultural DNA. In Japan, bamboo basket weaving (takekago) is considered a meditative practice, with different regions developing distinct styles based on local species. The UNESCO has recognized several rattan and bamboo weaving traditions as Intangible Cultural Heritage, including Vietnamese bamboo basket weaving and Philippine rattan craft.

These recognition programs have helped revitalize interest among younger generations. In Bali, the Bamboo Indigenous Knowledge program partners master craftsmen with design students, creating contemporary pieces that maintain traditional weaving patterns. “At first, I thought these old techniques were outdated,” admits 24-year-old designer Komang. “Then I realized each pattern contains generations of problem-solving—why waste centuries of innovation?”

This fusion approach appears in unexpected places. Medical researchers are studying traditional bamboo splinting methods for potential applications in emergency medicine, while automotive engineers examine rattan’s impact absorption properties for potential use in safety components. The very qualities that made these materials valuable to ancient traders—lightness, strength, flexibility—prove equally valuable in high-tech applications.

Economic Impacts and Future Directions

The global trade in rattan bamboo products supports an estimated 2.5 million artisans worldwide, primarily in rural communities where alternative employment may be scarce. Fair trade initiatives have demonstrated that when artisans receive proper compensation, they can invest in sustainable harvesting practices and train apprentices, creating virtuous cycles of cultural and environmental preservation.

Innovation continues at both grassroots and industrial levels. Scientists at the University of Singapore have developed a method of laminating bamboo strips that creates structural panels strong enough for multi-story construction. Meanwhile, in rural Thailand, communities are creating bamboo charcoal as a sustainable fuel source and developing rattan-based wastewater filtration systems.

The future likely holds more hybrid approaches—combining traditional knowledge with contemporary technology. As climate change intensifies, the low embodied energy and carbon sequestration potential of bamboo forests make them increasingly valuable. Rattan’s ability to produce economic value while maintaining forest ecosystems positions it as a key material in circular economy models.

From ancient trade routes to modern design studios, the story of rattan bamboo continues to unfold. These materials remind us that the most enduring solutions often come not from conquering nature, but from understanding its rhythms and working in concert with them. The conversation that began when a vine first wrapped around a tree continues in workshops, laboratories, and homes across the world—a testament to materials that bridge past and future through their timeless utility and beauty.

You may also like

Guangxi Zhuang Brocade Handmade Tote – Ethnic Boho Large-Capacity Shoulder Bag

Original price was: $172.00.$150.00Current price is: $150.00. Add to cartHandwoven Zhuang Brocade Tote Bag – Large-Capacity Boho Shoulder Bag

Original price was: $178.00.$154.00Current price is: $154.00. Add to cartBambooSoundBoost Portable Amplifier

Original price was: $96.00.$66.00Current price is: $66.00. Add to cartThe Palace Museum Paper-Cut Light Art Fridge Magnets: Chinese Cultural Style Creative Gift Series

Price range: $27.00 through $36.00 Select options This product has multiple variants. The options may be chosen on the product pageAncient Craftsmanship & ICH Herbal Beads Bracelet with Yellow Citrine & Silver Filigree Cloud-Patterned Luck-Boosting Beads

Original price was: $128.00.$89.00Current price is: $89.00. Add to cartAncient Craft Herbal Scented Bead Bracelet with Gold Rutile Quartz, Paired with Sterling Silver (925) Hook Earrings

Original price was: $322.00.$198.00Current price is: $198.00. Add to cart