Introduction to One-Piece Forging

One-piece forging represents one of the most sophisticated and reliable manufacturing processes in modern industry, creating components from a single piece of metal without welds, joints, or seams. This manufacturing technique transforms raw metal billets through controlled heating and precise mechanical force into complex, high-strength parts that maintain structural integrity across their entire form. Unlike assembly methods that combine multiple pieces, one-piece forging produces components with continuous grain flow that follows the part’s contours, resulting in superior mechanical properties and fatigue resistance.

The Science Behind Single-Piece Construction

The fundamental principle behind one-piece forging lies in its ability to eliminate weak points inherent in assembled structures. When metal is forged as a single unit, the material’s internal grain structure becomes aligned and refined, creating a homogeneous component free from the stress concentrations found at weld joints or mechanical fasteners. This process dates back centuries to blacksmiths hammering heated metal on anvils, but modern one-piece forging has evolved into a highly precise science utilizing hydraulic presses, mechanical hammers, and computer-controlled systems that can exert thousands of tons of pressure with millimeter accuracy.

Why One-Piece Forging Matters in Modern Manufacturing

Contemporary one-piece forging serves critical applications across aerospace, automotive, defense, and energy sectors where component failure is not an option. From jet engine turbine disks that must withstand extreme temperatures and rotational forces to automotive crankshafts enduring millions of stress cycles, one-piece forged components provide the reliability that assembled alternatives cannot match. The process continues to advance with new alloys, simulation technologies, and automated systems pushing the boundaries of what can be achieved through single-piece metal forming.

The Forging Process: From Raw Material to Finished Product

The journey of one-piece forging begins with carefully selected raw materials, typically high-quality alloy steel, titanium, aluminum, or nickel-based superalloys in the form of billets or bars. These materials are chosen based on the final component’s required mechanical properties, corrosion resistance, and operating environment. The initial step involves heating the raw material to precise temperatures in controlled atmosphere furnaces, bringing the metal to its optimal forging temperature where it becomes plastic enough to deform under pressure without cracking or developing internal defects.

Material Selection and Preparation

Material selection forms the foundation of successful one-piece forging. Engineers consider multiple factors including strength requirements, weight limitations, corrosion resistance, and thermal properties. For aerospace applications, titanium alloys offer exceptional strength-to-weight ratios, while high-strength steels dominate automotive applications. The ASTM International provides comprehensive standards for metal quality and composition, ensuring consistency across industrial applications. Before forging, materials undergo rigorous testing for chemical composition and internal integrity through ultrasonic and spectroscopic analysis.

Practical Tip: Material Testing Protocol

Implement a three-stage material verification process: chemical analysis to confirm alloy composition, ultrasonic testing to detect internal flaws, and mechanical testing to verify baseline properties. This comprehensive approach prevents defective materials from entering the forging process, reducing scrap rates by up to 25% according to industry data.

The Forging Operation: Precision Under Pressure

Once heated, the material moves to the forging press or hammer where immense force—ranging from hundreds to tens of thousands of tons—shapes it between precision-machined dies. Modern closed-die forging, the most common method for one-piece components, confines the metal within tool steel dies that define the part’s final geometry. As the press applies pressure, the metal flows to fill the die cavities, with excess material forming flash that is later trimmed away. This controlled deformation refines the metal’s microstructure, breaking down coarse grains and creating a fine, uniform grain structure that follows the component’s contours.

Case Study: Automotive Crankshaft Forging

A major automotive manufacturer reduced crankshaft failures by 60% after switching from cast to one-piece forged components. The forged crankshafts demonstrated superior fatigue resistance, withstanding over 10 million stress cycles in testing compared to 4 million for cast alternatives.

Post-Forging Treatments and Quality Assurance

Following the initial forging operation, components typically undergo additional processes including trimming, heat treatment, and machining. Heat treatment through quenching and tempering develops the desired mechanical properties by controlling the metal’s microstructure. Precision machining then brings critical dimensions and surface finishes to exact specifications. Throughout this sequence, quality control measures including ultrasonic testing, magnetic particle inspection, and dimensional verification ensure the final component meets stringent standards for integrity and performance. According to ASM International, proper heat treatment can increase forged component strength by 30-50% while improving toughness and fatigue resistance.

Practical Tip: Heat Treatment Optimization

Use computational modeling to predict the effects of different heat treatment parameters on final properties. This approach can reduce trial-and-error cycles by 70% and ensure optimal mechanical properties for specific applications.

Applications and Industries Benefiting from One-Piece Forging

The aerospace industry represents one of the most demanding applications for one-piece forging, where components must withstand extreme conditions while maintaining absolute reliability. Critical aircraft parts including landing gear components, engine mounts, turbine disks, and structural elements are predominantly manufactured through one-piece forging. These components benefit from the process’s ability to produce complex geometries with excellent strength-to-weight ratios and fatigue resistance—properties essential for aircraft safety and performance. The absence of welds eliminates potential failure points that could develop under cyclic loading during thousands of flight hours.

Aerospace and Aviation: Where Reliability is Non-Negotiable

In aerospace applications, one-piece forging delivers components that meet the extreme demands of flight operations. Jet engine fan disks, for instance, rotate at speeds exceeding 10,000 RPM while withstanding temperatures approaching 600°C. The Federal Aviation Administration mandates rigorous testing protocols for forged aerospace components, including fatigue testing that simulates decades of service in just months. Landing gear components forged as single pieces support aircraft weighing hundreds of tons during takeoff and landing, demonstrating the process’s capability to handle immense static and dynamic loads. A study published in Materials Science and Engineering confirmed that one-piece forged titanium components exhibit 40% higher fatigue life compared to assembled alternatives.

Case Study: Jet Engine Turbine Disk

A leading aerospace manufacturer achieved a 35% weight reduction in turbine disks by switching to one-piece forged nickel superalloys. The new design maintained required strength while improving fuel efficiency and reducing maintenance intervals.

Automotive Innovation: From Conventional to Electric Vehicles

Automotive manufacturing extensively utilizes one-piece forging for safety-critical components and high-performance applications. Crankshafts, connecting rods, steering knuckles, and wheel hubs forged as single pieces provide the durability needed to withstand the constant stress of engine operation and road conditions. In high-performance and racing vehicles, one-piece forged suspension components, transmission gears, and driveshafts offer superior strength and reliability compared to cast or assembled alternatives. The automotive industry’s shift toward electric vehicles has created new forging applications for motor shafts, rotor components, and battery enclosure elements that benefit from one-piece construction’s structural integrity. Statista research indicates the global automotive forging market will exceed $90 billion by 2025, driven by increasing demand for durable, lightweight components.

Practical Tip: EV Component Forging

When forging electric vehicle motor shafts, prioritize materials with excellent magnetic properties and fatigue resistance. Use simulation software to optimize grain flow direction for maximum torsional strength, typically achieving 20-30% improvement over conventional machining.

Energy and Heavy Industry: Powering Modern Civilization

Beyond transportation, one-piece forging serves vital roles in energy generation, heavy equipment, and defense sectors. Turbine shafts and generator components in power plants, drill string components in oil and gas extraction, and armored vehicle parts in military applications all leverage the superior mechanical properties of one-piece forged construction. These industries value the process’s ability to produce large, complex components that maintain integrity under extreme operational stresses, corrosive environments, and impact loads where assembled structures would likely fail. The U.S. Department of Energy highlights forged components as critical to renewable energy systems, particularly in wind turbine shafts and geothermal plant equipment where reliability directly impacts energy output and maintenance costs.

Case Study: Wind Turbine Shaft Forging

A renewable energy company extended maintenance intervals from 18 to 36 months by implementing one-piece forged main shafts in their 5MW wind turbines. The forged shafts demonstrated superior resistance to bending moments and torsional stresses common in wind energy applications.

Medical and Specialty Applications

The medical industry increasingly adopts one-piece forging for surgical instruments, implant components, and medical device parts. Forged surgical tools offer superior durability and precision compared to stamped or assembled alternatives, while orthopedic implants benefit from the enhanced biocompatibility and strength of single-piece construction. According to World Health Organization guidelines, medical device manufacturing requires stringent quality controls that align perfectly with the forging process’s inherent repeatability and traceability. Specialty applications extend to marine components, where forged propeller shafts and marine hardware resist corrosion in saltwater environments better than welded assemblies.

Practical Tip: Medical Implant Forging

For orthopedic implants, select titanium alloys with controlled oxygen content to optimize biocompatibility. Implement strict clean-room protocols during forging and heat treatment to prevent contamination that could compromise implant performance.

Future Developments in Forging Technology

The future of one-piece forging embraces digitalization, advanced materials, and sustainable manufacturing practices. Industry 4.0 technologies are transforming traditional forging operations through real-time monitoring, predictive maintenance, and data-driven process optimization. Smart forging presses equipped with IoT sensors collect thousands of data points during each operation, enabling manufacturers to fine-tune parameters for improved quality and efficiency. These advancements are particularly valuable for complex aerospace and medical components where consistency and precision are paramount.

Advanced Materials and Alloy Development

Material science innovations continue to expand the capabilities of one-piece forging. New nickel-based superalloys capable of withstanding temperatures above 1,000°C enable more efficient jet engines and power generation turbines. Aluminum-lithium alloys offer weight reductions of 10-15% while maintaining strength, making them ideal for aerospace applications. Research published in Nature Partner Journals demonstrates how nano-structured alloys can be successfully forged into complex components with enhanced mechanical properties. These material advances, combined with improved forging techniques, open new possibilities for components operating in extreme environments.

Practical Tip: New Alloy Implementation

When transitioning to advanced alloys, conduct small-scale pilot forging trials to establish optimal processing parameters. Document temperature ranges, deformation rates, and cooling cycles to develop reliable production protocols before full-scale implementation.

Digital Transformation and Simulation

Computer simulation has revolutionized forging design and process development. Finite element analysis (FEA) software accurately predicts metal flow, temperature distribution, and potential defects before physical tooling is created. This digital prototyping reduces development time and costs while optimizing material utilization. UNESCO recognizes digital manufacturing technologies as crucial for sustainable industrial development, noting their potential to reduce material waste by up to 30% in metal forming processes. Augmented reality systems now guide operators through complex forging sequences, while digital twins of forging equipment enable virtual testing and optimization.

Case Study: Digital Forging Implementation

A forging company reduced development time for new automotive components from 12 weeks to 4 weeks by implementing comprehensive digital simulation. The system accurately predicted 95% of potential forging defects, allowing for die modifications before manufacturing began.

Sustainability and Environmental Considerations

The forging industry increasingly focuses on environmental responsibility through energy-efficient processes, material recycling, and reduced emissions. Modern forging facilities implement closed-loop water systems, waste heat recovery, and electric induction heating that significantly reduce environmental impact compared to traditional methods. The Environmental Protection Agency reports that advanced forging technologies can reduce energy consumption by 20-30% while improving product quality. Additionally, the inherent material efficiency of one-piece forging—with typical material utilization rates exceeding 80%—contributes to sustainable manufacturing by minimizing waste.

Practical Tip: Energy Efficiency Measures

Implement variable frequency drives on press motors and optimize furnace insulation to reduce energy consumption. These measures typically achieve 15-25% energy savings while maintaining forging quality and throughput.

Additive Manufacturing Integration

Rather than replacing traditional forging, additive manufacturing (3D printing) complements the process by enabling rapid prototyping of forging dies and creating pre-forms with complex internal geometries. Hybrid approaches combine 3D-printed near-net-shape pre-forms with precision forging to achieve optimal material properties and dimensional accuracy. This integration reduces material waste and enables faster development of custom components. Research from Journal of Materials Processing Technology indicates that hybrid manufacturing approaches can reduce lead times by 40% while maintaining the superior mechanical properties of forged components.

Case Study: Hybrid Manufacturing Success

A defense contractor reduced material waste by 65% by combining 3D-printed titanium pre-forms with finish forging for complex missile components. The hybrid approach maintained required mechanical properties while significantly reducing machining time and material costs.

Practical Implementation and Best Practices

Successfully implementing one-piece forging requires careful planning and execution across multiple stages. Manufacturers should begin with comprehensive design analysis to identify potential stress concentrations and optimize component geometry for the forging process. Early collaboration between design engineers and forging specialists ensures manufacturability while maximizing mechanical performance. Material selection should balance performance requirements with cost considerations, considering the entire lifecycle of the component.

Design Guidelines for Optimal Results

Designing components for one-piece forging requires attention to specific principles that differ from those for machining or casting. Maintain consistent wall thicknesses where possible to ensure uniform material flow during forging. Incorporate generous fillets and radii at intersections to prevent stress concentrations and facilitate metal movement. Avoid sharp corners and deep, narrow cavities that can challenge die filling. Consider draft angles of 3-7 degrees to enable proper part ejection from dies. These design considerations, when implemented during the conceptual phase, significantly improve forging success rates and component quality.

Practical Tip: Design for Forging Checklist

Use this checklist during design reviews: uniform wall thickness (variation < 25%), minimum fillet radius = 1.5x wall thickness, draft angles 3-7°, avoid undercuts, and maintain symmetry where possible. Following these guidelines typically improves first-time forging success by 40%.

Quality Control and Testing Protocols

Implementing robust quality control systems is essential for one-piece forged components, particularly in safety-critical applications. Establish clear acceptance criteria for material certifications, dimensional accuracy, and mechanical properties. Non-destructive testing methods including ultrasonic, radiographic, and dye penetrant inspection should be standard procedures. Maintain detailed process documentation for traceability, recording parameters such as heating temperatures, forging pressures, and heat treatment cycles. Regular calibration of measurement equipment and third-party verification of testing procedures ensure consistent quality across production runs.

Practical Tip: Quality Documentation System

Implement a digital quality management system that automatically records all process parameters and test results. This creates complete traceability for each component and enables statistical process control to identify trends before they affect quality.

Cost Optimization Strategies

While one-piece forging offers superior performance, cost management remains crucial for commercial viability. Consider production volume when selecting between open-die and closed-die forging—higher volumes typically justify the higher initial tooling costs of closed-die processes. Optimize material usage through careful billet sizing and nesting multiple components within single forgings where practical. Implement preventive maintenance programs for forging equipment to minimize unplanned downtime. Leverage digital simulation to identify potential issues before committing to physical tooling, reducing development costs and time-to-market.

Case Study: Cost Reduction Initiative

A manufacturing company reduced forging costs by 22% through material optimization and process improvements. Key strategies included implementing nested forging for small components, optimizing billet sizes to reduce scrap, and using predictive maintenance to increase equipment uptime.

Conclusion: The Enduring Value of One-Piece Forging

One-piece forging continues to demonstrate its indispensable role in modern manufacturing, combining centuries-old metalworking principles with cutting-edge technology. The process’s ability to produce components with unmatched structural integrity, fatigue resistance, and reliability ensures its continued relevance across aerospace, automotive, energy, and medical industries. As digitalization, advanced materials, and sustainable practices transform manufacturing, one-piece forging evolves to meet new challenges while maintaining its fundamental advantages. For engineers and manufacturers seeking the ultimate in component performance and durability, one-piece forging remains the gold standard for critical applications where failure is not an option.

The future promises even greater integration of digital technologies, material innovations, and environmentally conscious practices that will expand forging capabilities while reducing environmental impact. As industries continue to demand higher performance from smaller, lighter components, one-piece forging will play an increasingly vital role in turning these requirements into reality. The process’s unique combination of art and science—honed over generations and enhanced by modern technology—ensures its place at the forefront of advanced manufacturing for decades to come.

You may also like

BambooSoundBoost Portable Amplifier

Original price was: $96.00.$66.00Current price is: $66.00. Add to cartAncient Craftsmanship & ICH Herbal Beads Bracelet with Yellow Citrine & Silver Filigree Cloud-Patterned Luck-Boosting Beads

Original price was: $128.00.$89.00Current price is: $89.00. Add to cartAncient Craft Herbal Scented Bead Bracelet with Gold Rutile Quartz, Paired with Sterling Silver (925) Hook Earrings

Original price was: $322.00.$198.00Current price is: $198.00. Add to cartGuangxi Zhuang Brocade Handmade Tote – Ethnic Boho Large-Capacity Shoulder Bag

Original price was: $172.00.$150.00Current price is: $150.00. Add to cartHandwoven Zhuang Brocade Tote Bag – Large-Capacity Boho Shoulder Bag

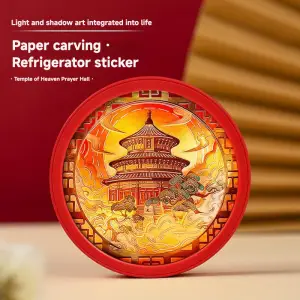

Original price was: $178.00.$154.00Current price is: $154.00. Add to cartThe Palace Museum Paper-Cut Light Art Fridge Magnets: Chinese Cultural Style Creative Gift Series

Price range: $27.00 through $36.00 Select options This product has multiple variants. The options may be chosen on the product page